In the medical field, injection molding processing is a key technology for manufacturing various medical products, and material selection is an extremely crucial part of this technology. Since medical products are directly related to the health and safety of patients, medical injection molding processing has extremely strict and multi-faceted requirements for material selection. The following are the main considerations for material selection:

-

Biocompatibility: The cornerstone of protecting human safety

Biocompatibility is the primary criterion for selecting medical injection molding materials. This means that the selected materials must be highly compatible with human tissues and should not trigger allergic reactions or rejection phenomena. After all, any adverse reactions between the materials and the human body could potentially cause serious health damage to patients. Therefore, in medical injection molding processing, non-toxic and harmless medical-grade plastic raw materials are often preferred to safeguard patient safety from the source.

-

Durability: Withstanding daily use and sterilization

Medical products are frequently subjected to wear and tear during daily use and also need to undergo various sterilization processes. This requires the materials to have sufficient strength and durability to withstand these challenges. Only in this way can medical products maintain stable performance during long-term use and provide reliable services to patients. For example, for the injection-molded parts of some surgical instruments, if the material durability is insufficient, they may be damaged after frequent use and sterilization, which could then affect the smooth progress of surgeries.

-

Transparency and color: Balancing accurate observation and aesthetics

For some medical supplies, such as catheters and infusion sets, transparency is a key indicator for material selection. High transparency allows medical staff to clearly observe the state of the fluid, such as the flow rate of the liquid and the presence of air bubbles, enabling them to make accurate judgments and take timely actions. In addition, uniform and non-fading color of the materials is also very important. This not only concerns the aesthetic appearance of the products but can also, to a certain extent, avoid misjudgments caused by color changes.

-

Sterility and ease of cleaning: A line of defense against infection risks

The medical environment has extremely high requirements for sterility, so materials should have good sterility and ease of cleaning. They should not only be easy to clean and sterilize but also should not produce any harmful substances during the cleaning and sterilization processes to avoid causing secondary harm to patients. At the same time, the materials themselves should preferably have certain antibacterial properties, which can to some extent inhibit the growth of bacteria and further reduce the risk of infection, building a solid defense for patients' health.

-

Environmental friendliness: Considering the long-term impact of medical waste

With the increasing awareness of environmental protection, the disposal of medical waste has received increasing attention. In medical injection molding processing, choosing recyclable or biodegradable materials has become a trend. Such materials can reduce environmental pollution after the products have completed their medical use, in line with the concept of sustainable development. For example, some biodegradable plastic materials can gradually decompose in the natural environment after fulfilling their medical missions, reducing the pressure on the ecosystem.

-

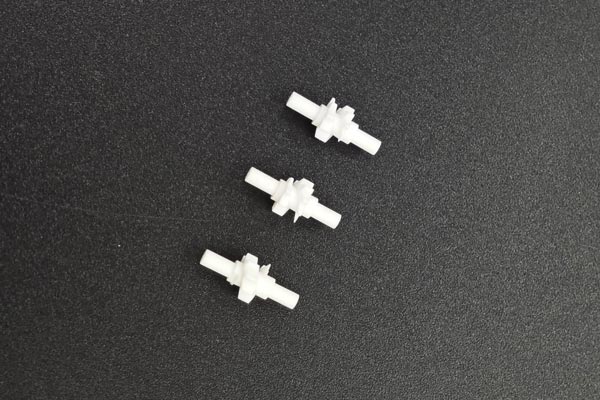

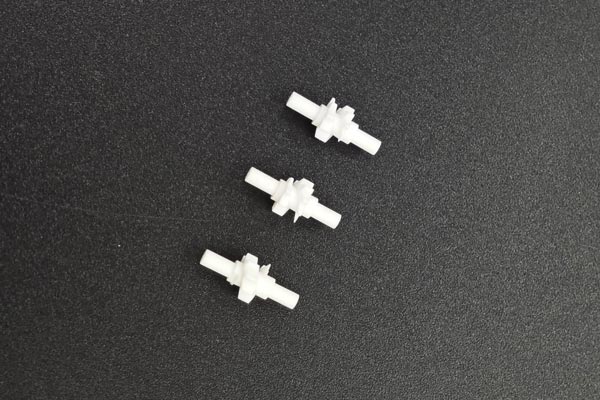

Processability: Ensuring the smooth progress of injection molding

The processability of materials directly affects the quality and efficiency of medical injection molding processing. Good processability includes appropriate fluidity, thermal stability, and color stability. Materials with good fluidity can smoothly fill the mold during the injection molding process, reducing the occurrence of defects; materials with strong thermal stability are not prone to decomposition and deterioration under high-temperature processing conditions, ensuring stable product quality; and color stability can ensure consistent color of products in different production batches, improving the overall quality of the products. Only when materials have these excellent processability characteristics can the injection molding process proceed smoothly and high-quality medical products be produced.

-

Cost-effectiveness: Balancing quality and economy

On the premise of meeting the above requirements, cost-effectiveness is also an unignorable factor in material selection. The manufacturing cost of medical products will directly affect their market price and accessibility. Therefore, when selecting materials, it is necessary to comprehensively consider factors such as the price, performance, and service life of the materials, striving to reduce manufacturing costs while ensuring product quality and safety, so that more patients can benefit.

In conclusion, medical injection molding processing needs to comprehensively and comprehensively consider multiple aspects such as biocompatibility, durability, transparency, color, sterility, ease of cleaning, environmental friendliness, processability, and cost-effectiveness when selecting materials. Only by carefully selecting appropriate materials can safe, effective, and reliable medical products be manufactured to safeguard the health of patients.

Home

Home