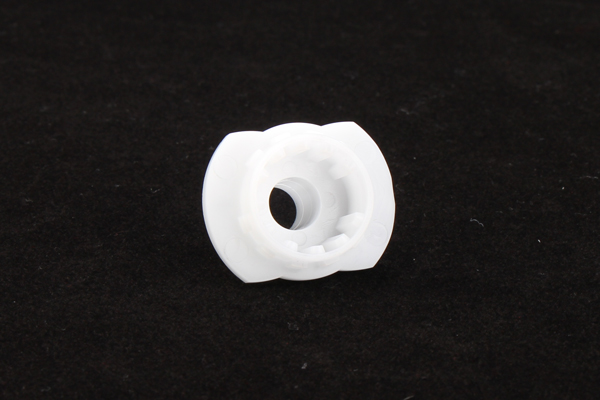

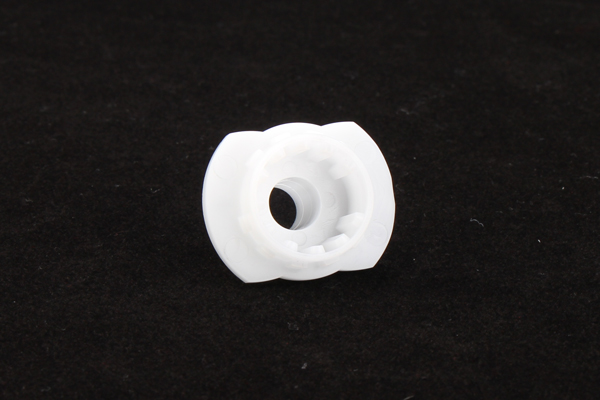

Medical injection-molded products are indispensable components in modern healthcare systems, widely used in surgical instruments, diagnostic devices, implants, and disposable consumables. Their quality directly impacts patient safety and treatment outcomes, demanding stringent stability and reliability. However, cracking caused by material, process, or design flaws remains a common challenge in the industry. This article explores the causes, solutions, and preventive measures for cracking in medical injection-molded products.

1. Common Causes of Cracking

-

Material Selection Issues: Insufficient toughness (e.g., non-high-impact polypropylene or non-medical-grade PC alloys), poor temperature resistance (e.g., PP embrittlement after high-temperature sterilization), or excessive recycled material content.

-

Process Defects:

-

Improper temperature control leading to material degradation or poor flowability.

-

Unbalanced pressure/speed causing incomplete filling or excessive flash.

-

Uneven cooling resulting in residual stress due to inconsistent shrinkage.

-

Mold Design Flaws:

-

Irrational runner/gate design causing shear heat concentration.

-

Insufficient draft angles leading to surface cracks during ejection.

-

Poor ejection system layout causing localized deformation.

-

Post-Processing and Usage Risks:

-

Sterilization methods (e.g., EO gas causing embrittlement, steam sterilization inducing thermal stress).

-

Long-term storage or transportation vibrations exacerbating hidden cracks.

2. Solutions to Cracking

-

Material Optimization:

-

Use medical-grade specialized materials (e.g., PPSU, PEEK) and validate thermal stability via DSC testing.

-

Limit recycled material to ≤10% and add toughening agents.

-

Process Adjustments:

-

Optimize melt temperature (e.g., 280–320°C for PC) and adopt multi-stage injection to reduce shear stress.

-

Extend packing time (50–70% of injection time) and ensure uniform mold temperature (±2°C tolerance).

-

Mold Improvements:

-

Redesign runners with hot runner technology and optimize gate positions.

-

Increase draft angles (≥1°) and use pneumatic ejection systems.

-

Simulate filling via Moldflow to identify stress concentration zones.

-

Enhanced Post-Processing:

-

Replace EO sterilization with low-temperature plasma methods or adjust steam parameters (121°C/15 min).

-

Conduct drop tests (1m height) and fatigue testing (100,000 cycles) to validate crack resistance.

3. Preventive Measures and Long-Term Management

-

Establish a Full-Process QC System:

-

Implement batch traceability from raw materials to finished products and deploy AI vision inspection for micro-cracks (0.01mm accuracy).

-

Strengthen Supplier Collaboration:

-

Co-develop customized material formulas with suppliers (e.g., nano-fillers for impact resistance).

-

Audit mold makers regularly to ensure compliance with ISO 2768-m standards.

-

Continuous Technological Innovation:

-

Adopt 3D-printed molds to shorten trial cycles (1–2 weeks vs. traditional 4–6 weeks).

-

Apply digital twin technology for virtual process optimization.

Conclusion

Addressing cracking in medical injection-molded products requires a multifaceted approach encompassing material selection, process refinement, mold design, and rigorous testing. By leveraging advanced technologies and collaborative supply chain management, manufacturers can reduce defect rates (target ≤0.1%) and enhance product safety for patients. Future advancements in biodegradable materials and smart manufacturing will drive the industry toward higher precision and customization.

Home

Home