In the field of medical device manufacturing, injection molding technology stands as a core process for producing critical components such as catheter connectors, surgical instrument handles, and in-vitro diagnostic equipment housings, owing to its high precision, efficiency, and scalability. However, discoloration issues that arise during the injection molding of medical-grade plastics not only compromise product appearance consistency but may also lead to biocompatibility failures due to material degradation, directly threatening patient safety. This article systematically explores the root causes and solutions of discoloration in medical injection molding based on industry practices and typical cases, covering the entire chain from raw materials to processes.

I. Material System: Intrinsic Inducers of Discoloration Risks

1. Raw Material Contamination and Degradation

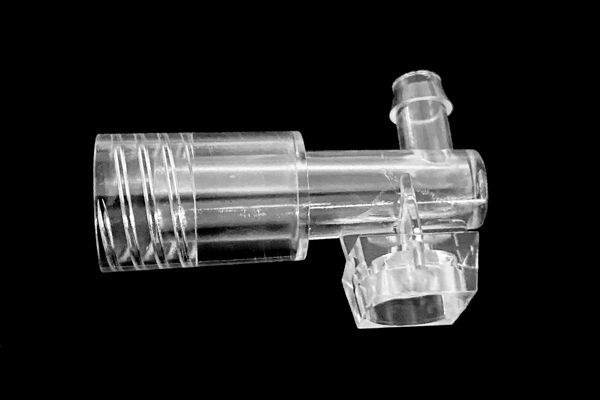

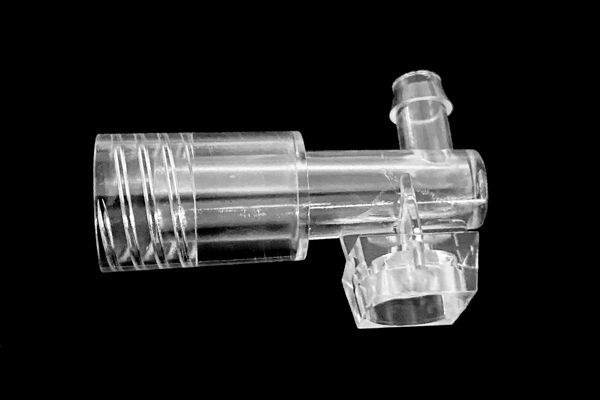

Medical-grade plastics (e.g., PEEK, PEI, TPE) are highly sensitive to impurities. A medical device company once experienced yellow-brown patches on product surfaces due to excessive moisture (0.3%) in PP raw materials caused by substandard storage humidity, far exceeding the 0.02% process limit. The moisture triggered violent hydrolysis at 260°C. Additionally, mismatched thermal stability between color masterbatches and base materials is a common issue. For instance, a catheter connector using PEI (heat-resistant up to 280°C) with a general-purpose color masterbatch rated for only 240°C resulted in black particles from colorant decomposition during injection molding.

2. Imbalanced Additive Systems

Excessive lubricants (e.g., zinc stearate) can cause migration-induced discoloration. A company increased lubricant content from 1% to 3% to improve demolding, resulting in surface whitening and a 40% drop in friction coefficient. More covert risks stem from antioxidant failure. Without replenishing hindered phenol antioxidants during prolonged high-temperature processing, polycarbonate (PC) materials generate quinone-based chromophores through oxidative chain scission, causing transparent parts to gradually yellow.

II. Equipment Conditions: Invisible Drivers of Discoloration

1. Temperature Control Inaccuracy

Thermocouple calibration drift is a primary cause of temperature runaway. A thermocouple in an injection molding machine drifted by 0.5°C annually, leading to an 8°C temperature overshoot after three years. At 320°C, PPS material underwent excessive pyrolysis, generating conjugated double-bond structures that turned products dark brown. Additionally, design flaws in nozzle-barrel connections create "dead zones" where material degrades. A company extended material replacement intervals from 12 to 72 hours and reduced discoloration defects by 82% by replacing conventional straight nozzles with self-locking designs.

2. Uncontrolled Shear Stress

The synergy between screw speed and backpressure is critical. A company producing minimally invasive surgical forceps handles shortened cycle times by increasing screw speed from 80 rpm to 120 rpm and backpressure from 120 bar to 180 bar. The high shear force raised PA66 material temperature by 35°C, causing amide bond scission and colored product formation. Multi-stage backpressure control (80 bar during plasticization, 150 bar during packing) maintained plasticization quality while reducing discoloration to below 0.3%.

III. Mold Design: Determinative Process Boundaries

1. Gating System Defects

Undersized gates induce localized overheating. A company using a 0.3 mm pin-point gate for 0.2 mm-thick endoscope catheters generated shear rates of 15,000 s⁻¹, far exceeding PEEK's 8,000 s⁻¹ limit, causing silver streak discoloration. Enlarging the gate to 0.8 mm and adopting a fan gate design reduced shear rates to 6,000 s⁻¹, eliminating defects.

2. Venting System Failure

Inadequate mold venting leads to material charring. A company producing cardiac stent delivery systems encountered carbonization due to 0.005 mm-deep venting slots (standard: 0.02–0.05 mm), with 0.5 MPa compressed gas overheating PEU material at 380°C. Deepening slots to 0.03 mm and adding 0.1 mm-wide venting steel on parting surfaces reduced charring defects from 15% to 0.2%.

IV. Process Parameters: The Art of Dynamic Control

1. Multi-Stage Injection Strategy

A company producing blood glucose meter housings adopted a "fast-slow-fast" three-stage injection: 80% speed for runner filling, 30% for thin-wall zones, and 90% for packing. This strategy reduced PP material shear stress variation, cutting discoloration from 5% to 0.8% compared to single-stage injection.

2. Packing Curve Optimization

Matching packing pressure with time is crucial. A company producing dialysis filter end caps observed white haze when increasing packing pressure from 120 MPa to 150 MPa. Moldflow simulations revealed reverse material flow near the gate caused by high pressure, inducing localized stress whitening. A "120 MPa/3s → 100 MPa/5s → 80 MPa/7s" decreasing packing curve eliminated haze defects.

V. Typical Case: Tackling Discoloration in Medical Dehumidifier Housings

A company producing medical-grade dehumidifier housings (material: toughened PP) encountered batch discoloration. Systematic investigations revealed:

-

Raw materials: The color masterbatch supplier unilaterally changed carrier resins, reducing heat resistance from 260°C to 230°C.

-

Equipment: Damaged barrel heating coils caused ±15°C temperature fluctuations.

-

Process: Constant 80 mm/s injection speed lacked multi-stage control.

-

Mold: The 2.5 mm gate diameter (standard: ≥3.5 mm) was undersized.

Improvements:

-

Switched to 280°C-rated color masterbatches.

-

Installed infrared thermometers for real-time barrel temperature monitoring.

-

Adopted "50 mm/s → 30 mm/s → 70 mm/s" three-stage injection.

-

Enlarged gates to 4 mm and switched to submarine gates.

Post-implementation, product color difference (ΔE) dropped from 4.2 to 0.8, meeting medical appearance standards.

VI. Industry Solution Framework

-

Material control: Establish thermal stability databases for raw materials, requiring suppliers to provide DSC decomposition temperature data.

-

Equipment maintenance: Implement TPM (Total Productive Maintenance) with thermocouple calibration every 3 months for medical injection molding machines.

-

Mold management: Optimize gating systems via CAE simulations to keep shear rates ≤80% of material critical values.

-

Process standardization: Develop medical injection molding process cards specifying parameter tolerances (e.g., ±2°C for melt temperature, ±5% for injection speed).

-

Quality tracing: Deploy MES systems for end-to-end traceability from raw material batches to finished product barcodes.

The resolution of discoloration issues in medical plastic injection molding demands a five-dimensional control system integrating materials, equipment, molds, processes, and inspection. With the deepening implementation of ISO 13485:2016 quality management systems and the adoption of intelligent injection technologies (e.g., AI parameter optimization, inline color difference detection), the medical injection molding industry is steadily advancing toward zero-defect manufacturing. Only by embedding quality awareness into every process detail can enterprises solidify safety baselines and earn dual trust from patients and markets.

Home

Home