Medical injection molding, a core process in medical device manufacturing, directly impacts product supply stability and cost control. However, production lag—manifesting as extended cycle times, reduced yield rates, or frequent equipment downtime—frequently occurs. This phenomenon stems from multifaceted factors spanning technology, management, supply chains, and external environments. This article systematically analyzes the root causes of lag in medical injection molding production and proposes targeted improvement strategies.

1. Technical Limitations: Process Control and Equipment Performance

-

Mold Design and Manufacturing Defects: High precision requirements in medical molds make minor flaws (e.g., unbalanced runner systems, inefficient cooling channels) prone to causing uneven filling, warping, or ejection failures. For instance, imbalanced multi-cavity molds may lead to inconsistent cavity filling times, necessitating repeated parameter adjustments or mold repairs.

-

Material-Process Mismatch: Medical-grade plastics (e.g., PPSU, PEEK) demand precise control of melt temperature, injection speed, and packing pressure. Deviations from supplier-recommended parameters can trigger defects like sink marks, burns, or silver streaks, resulting in batch rejections. The adoption of novel biodegradable materials further complicates process adaptability, requiring extensive DOE experiments for parameter optimization—a process that prolongs production setup.

-

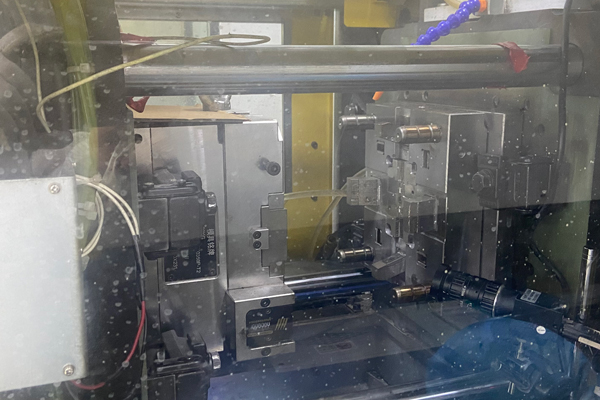

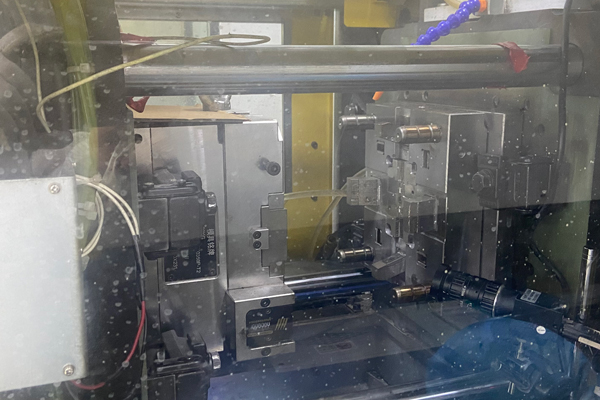

Equipment Aging and Poor Maintenance: Hydraulic leaks, screw wear, or electronic control failures in injection molding machines reduce operational stability. Strict cleanliness standards in medical manufacturing exacerbate risks; inadequate maintenance may introduce contaminants (e.g., oil, metal shavings), triggering quality incidents and production halts for rectification.

2. Management Failures: Process Coordination and Quality Control

-

Production Planning and Material Supply Misalignment: Small-batch, high-mix production models in medical manufacturing require careful scheduling of mold changes and material transitions. For example, failure to pre-stock specialty color masterbatches led to a 3-day delivery delay for one company, costing over $1 million.

-

Quality Control Gaps: Compliance with ISO 13485 demands rigorous inspection protocols, but redundant processes or flawed sampling plans can backfire. Over-reliance on final inspections may allow defective parts to progress downstream, increasing rework costs, while excessive inspection frequencies reduce equipment utilization.

-

Skill Shortages and Training Gaps: Injection molding operators require cross-disciplinary knowledge of material science, mold design, and equipment mechanics. However, industry-wide talent gaps persist, with novice technicians frequently causing mold damage due to incorrect parameter settings—a single incident can cost tens of thousands of dollars in repairs and disrupt production continuity.

3. Supply Chain Risks: External Dependencies and Unforeseen Disruptions

-

Raw Material Volatility: The medical plastics market’s high concentration leaves manufacturers vulnerable to supplier capacity constraints or geopolitical risks. During the 2021 global chip shortage, some firms faced 2-week production halts due to controller chip shortages for injection molding machines.

-

Outsourcing Vulnerabilities: Cost-driven outsourcing of mold fabrication or sterilization processes introduces quality variability. One company experienced a 60% reduction in mold lifespan after outsourcing heat treatment to a non-compliant supplier, forcing premature mold replacement and revalidation.

4. External Pressures: Regulatory and Environmental Changes

-

Evolving Compliance Demands: New regulations like the EU’s MDR impose stricter biocompatibility and traceability requirements, forcing firms to re-certify materials or upgrade labeling systems—a process that disrupts production schedules.

-

Unforeseen Crises: The COVID-19 pandemic exposed vulnerabilities, with surging demand for ventilator components overwhelming firms lacking contingency plans. Labor shortages and logistics paralysis prolonged capacity recovery by months.

5. Systemic Improvement Strategies

-

Digital Transformation: Deploy MES systems for real-time production data analytics and AI-driven equipment failure prediction to optimize scheduling.

-

Supply Chain Resilience: Establish strategic stockpiles with key suppliers and diversify material sourcing to localize procurement.

-

Standardization and Modularization: Adopt family molds to reduce changeover times and build process parameter databases to shorten setup cycles.

-

Workforce Development: Partner with vocational schools to create specialized medical injection molding programs and implement mentorship systems to preserve operational expertise.

Conclusion

Lag in medical injection molding production arises from the interplay of technical, managerial, supply chain, and external factors. A holistic approach integrating preventive monitoring, rapid response mechanisms, and continuous innovation is essential to balance quality assurance with production efficiency, ensuring a robust medical supply chain.

Home

Home