In the field of injection molding for medical products, main runner adhesion is a common problem that affects production efficiency and product quality. Given the stringent requirements for material purity, dimensional accuracy, and surface finish in medical products, the issue of main runner adhesion can not only lead to production interruptions but also cause surface defects and even contamination risks in products. This article will systematically analyze the causes of main runner adhesion from four dimensions: mold design, process parameters, material characteristics, and equipment maintenance, and propose targeted solutions.

I. Mold Design Defects: Hidden Dangers in Structural Design

-

Unreasonable Main Runner Dimensions

Excessively small diameters or overly long lengths of the main runner can increase the flow resistance of the molten material and accelerate the cooling rate. For instance, when the small-end diameter of the main runner is less than 0.5 - 1 mm of the nozzle orifice diameter, the molten material is prone to strong adhesion to the inner wall of the mold due to uneven shrinkage after injection. Additionally, the absence of a cold slug well design or insufficient capacity of the cold slug well in the main runner can cause the front-end cold material to remain, further exacerbating the risk of adhesion.

-

Insufficient Surface Finish

If there are chisel marks, scratches, or peeling of the electroplated layer on the mold cavity surface, the demolding resistance will be significantly increased. Medical-grade molds require chrome plating or nano-coating treatment to ensure a surface roughness of Ra ≤ 0.05 μm. For soft rubber materials such as thermoplastic elastomers (TPE/TPU), excessive polishing can actually enhance the adhesion force. In such cases, electrical discharge machining should be used to retain discharge marks of 0.01 - 0.03 mm to reduce the friction coefficient.

-

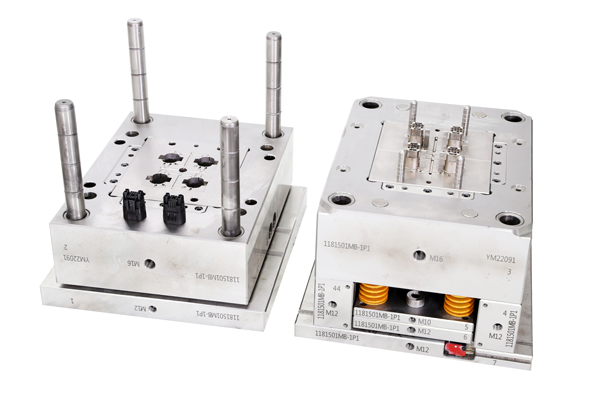

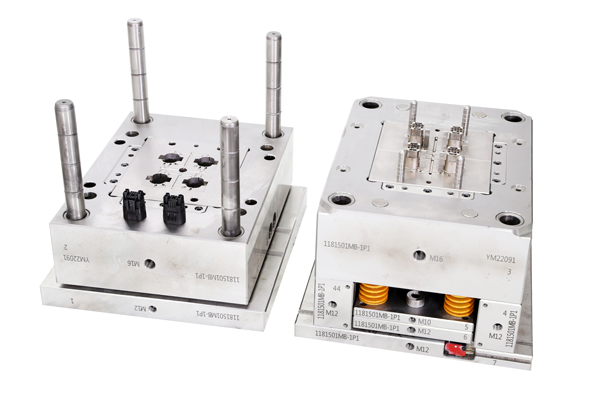

Improper Matching between the Sprue Bushing and the Nozzle

The concave radius of the sprue bushing should be 1 - 2 mm larger than the spherical radius of the nozzle. If the clearance between them is too large, the molten material will seep into the gap and form flash; if the clearance is too small, it will lead to pressure loss during injection. A medical catheter manufacturing enterprise once experienced a surge in the main runner adhesion rate to 15% due to a deviation of 0.3 mm in the R-angle of the sprue bushing. After adjustment, the failure rate dropped to below 0.5%.

II. Uncontrolled Process Parameters: Chain Reactions of Thermomechanical Imbalance

-

Improper Temperature Management

-

Excessive Barrel Temperature: When the temperature exceeds the thermal decomposition temperature of the material (e.g., when the temperature of PC material exceeds 320°C), the molten material will carbonize and adhere to the mold surface.

-

Abnormal Mold Temperature: Excessively high fixed mold temperature will keep the material in the main runner area continuously softened, while excessively low moving mold temperature will cause uneven shrinkage. It is recommended to use a mold temperature controller for zonal control, with a temperature difference of 5 - 10°C between the front and rear molds.

-

Low Nozzle Temperature: If the nozzle temperature is more than 20°C lower than the flow temperature of the molten material, a cold hard layer will form at the entrance of the main runner, increasing the demolding resistance.

-

Imbalance between Pressure and Time

-

Excessive Injection Pressure: Injection pressures exceeding the yield strength of the material will cause the molten material to penetrate into micro-cracks in the mold, forming mechanical interlocking. The injection pressure for medical-grade PPSU material should be controlled within 80 - 120 MPa.

-

Excessive Holding Pressure Time: Continuous holding pressure will cause over-filling of the material and reduce the shrinkage rate of the main runner. It is recommended that the holding pressure time should not exceed 30% of the cooling time.

-

Insufficient Cooling Time: If the mold is opened when the main runner is not fully solidified, adhesion may occur due to the elastic deformation of the material. For a main runner with a thickness of 3 mm, the cooling time should be ≥ 8 seconds.

III. Material Characteristics and Pre-treatment: Explicit Manifestation of Hidden Factors

-

Differences in Material Flowability

There are significant differences in the flowability of medical-grade materials such as PEEK (melt index: 0.5 - 5 g/10 min) and PP (melt index: 10 - 30 g/10 min). For low-flowability materials, the barrel temperature should be increased by 10 - 20°C, and the main runner diameter (usually 1.5 - 2 times the wall thickness of the product) should be appropriately enlarged in design to compensate.

-

Insufficient Pre-drying

If the moisture content of hygroscopic materials such as PA66 exceeds 0.2%, hydrolysis will occur at high temperatures, generating gas and forming bubble pores on the surface of the main runner, which increases the risk of adhesion. It is recommended to use a desiccant dryer to ensure a dew point temperature of ≤ -40°C and a drying time of 4 - 6 hours.

-

Influence of Additives

Lubricants (such as zinc stearate) added to enhance biocompatibility may cause uneven local demolding performance if not evenly distributed. In a case study of a heart stent mold, increasing the lubricant content from 1% to 2% reduced the main runner adhesion rate by 60%.

IV. Lack of Equipment Maintenance: A Fatal Blow from Accumulated Wear

-

Insufficient Mold Rigidity

Long-term use can cause wear on the mold guide posts, leading to misalignment between the moving and fixed molds. A misalignment of more than 0.05 mm in the main runner can cause adhesion. It is recommended to perform laser interferometer detection every 50,000 mold cycles and replace the guide posts or re-match the molds if the misalignment exceeds the standard.

-

Ejector System Failure

If the bending of the ejector pins exceeds 0.02 mm or the parallelism error is > 0.05 mm, uneven force will be applied to the main runner. An infusion set injection molding enterprise increased the number of ejector pins from 2 to 4 and extended the ejection stroke by 2 mm, resulting in a 40% increase in the demolding force.

-

Thermal Runaway of the Hot Runner System

A temperature fluctuation of more than ±5°C in the hot runner nozzle can cause uneven material properties at the entrance of the main runner. It is recommended to use a PID intelligent temperature control system and record the temperature curve every 24 hours. Replace the heating coils or thermocouples immediately if abnormalities are detected.

V. Comprehensive Solutions: Four-dimensional Collaborative Optimization

-

Mold Design Optimization

-

Use Moldflow simulation to analyze the flow field of the main runner and optimize the gate position and size.

-

For complex medical products, design a delayed ejection mechanism to separate the main runner first and then demold the product.

-

Intelligent Control of Process Parameters

-

Introduce an IoT system for the injection molding machine to monitor the melt temperature and pressure curves in real-time and automatically adjust the parameters.

-

Establish a dedicated process database for medical products to achieve rapid switching between different materials.

-

Full Lifecycle Management of Materials

-

Collaborate with suppliers to build a material traceability system to ensure that each batch of raw materials has complete biocompatibility certificates and test reports.

-

Use a central material supply system to avoid contamination introduced by manual material feeding.

-

Preventive Maintenance of Equipment

-

Develop a three-level maintenance system for molds (daily inspection, weekly maintenance, and monthly overhaul).

-

Implement condition monitoring for key equipment (such as the hot runner system) and predictively replace wearing parts.

Conclusion

The issue of main runner adhesion in the injection molding of medical products is essentially a systemic competition among mold design, process control, material characteristics, and equipment status. By introducing tools such as Design Failure Mode and Effects Analysis (DFMEA) and Process Failure Mode and Effects Analysis (PFMEA), and combining them with intelligent manufacturing technologies, a transition from passive maintenance to proactive prevention can be achieved. A Class III medical device enterprise reduced the downtime caused by main runner adhesion from 12 hours per month to 1.5 hours and increased the first-pass yield of products to 99.8% through the above comprehensive improvements, providing a replicable lean production model for the industry.

Home

Home