- Home

-

Products and Services

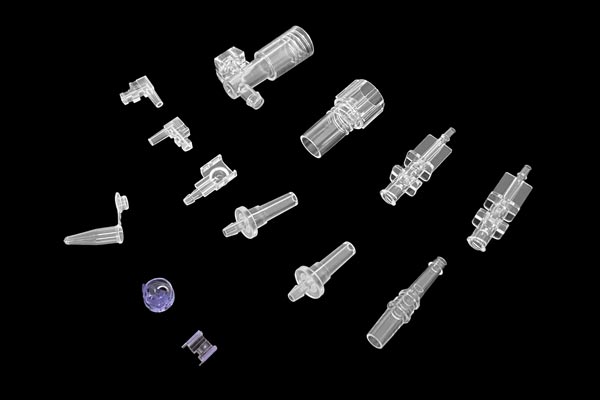

Medical Implantable ProductsYize Mould focuses on the R&D, design, manufacturing and sales of precision medical injection molds, and has developed into a large-scale "mold-plastic integration" manufacturer, dedicated to providing solutions and final products for medical molds, medical devices, medical consumables, and pharmaceutical packaging.Medical DevicesYize Mould focuses on the R&D, design, manufacturing and sales of precision medical injection molds, and has developed into a large-scale "mold-plastic integration" manufacturer, dedicated to providing solutions and final products for medical molds, medical devices, medical consumables, and pharmaceutical packaging.Cleaning and AssemblyYize Mould focuses on the R&D, design, manufacturing and sales of precision medical injection molds, and has developed into a large-scale "mold-plastic integration" manufacturer, dedicated to providing solutions and final products for medical molds, medical devices, medical consumables, and pharmaceutical packaging.Medical PackagingYize Mould focuses on the R&D, design, manufacturing and sales of precision medical injection molds, and has developed into a large-scale "mold-plastic integration" manufacturer, dedicated to providing solutions and final products for medical molds, medical devices, medical consumables, and pharmaceutical packaging.Medical LSR Molding

-

Medical Moulds

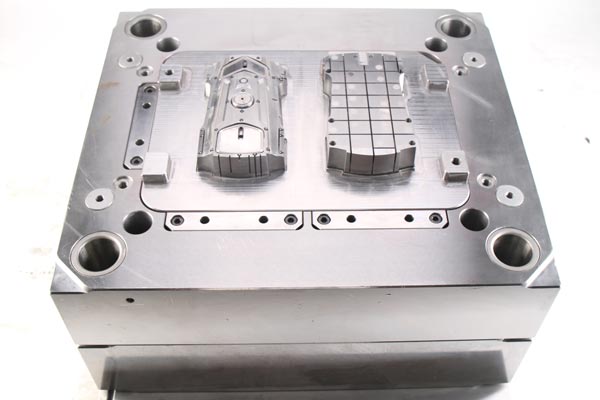

Medical mouldsYize Mould, a professional manufacturer of molds and accessories, we have 100 professional mold makers. The precision of mold accessories can reach 0.001mm, and the overall precision of the mold can reach 0.005mm.

-

Our Advantages

Medical mouldsSince the company was founded, Yize Mould has always been technology-oriented as the core, integrating the R&D, design and manufacturing of precision molds, and gradually becoming a professional manufacturer of precision medical molds, medical products and fluorine products.Medical injection molded productsSince the company was founded, Yize Mould has always been technology-oriented as the core, integrating the R&D, design and manufacturing of precision molds, and gradually becoming a professional manufacturer of precision medical molds, medical products and fluorine products.

- QC System

- Our ESG

-

About Us

HistorySince the company was founded, Yize Mould has always been technology-oriented as the core, integrating the R&D, design and manufacturing of precision molds, and gradually becoming a professional manufacturer of precision medical molds, medical products and fluorine products.Corporate CultureSince the company was founded, Yize Mould has always been technology-oriented as the core, integrating the R&D, design and manufacturing of precision molds, and gradually becoming a professional manufacturer of precision medical molds, medical products and fluorine products.Talent conceptSince the company was founded, Yize Mould has always been technology-oriented as the core, integrating the R&D, design and manufacturing of precision molds, and gradually becoming a professional manufacturer of precision medical molds, medical products and fluorine products.NewsSince the company was founded, Yize Mould has always been technology-oriented as the core, integrating the R&D, design and manufacturing of precision molds, and gradually becoming a professional manufacturer of precision medical molds, medical products and fluorine products.

- Contact