The precision control of medical mold injection products stands as a core technical indicator in modern medical device manufacturing, with its precision level directly influencing product functionality, safety, and clinical applicability. In the field of precision manufacturing, the dimensional tolerances, geometric accuracy, and surface quality of medical injection-molded parts must achieve sub-micron to micron-level standards. Breakthroughs in this technical boundary rely on a multidisciplinary technical system.

I. Technical Indicator System for Precision Control

Precision control of medical mold injection products encompasses three dimensions: dimensional accuracy, geometric accuracy, and surface quality. In terms of dimensional accuracy, ultra-precision molds can control critical dimensional tolerances within the range of ±0.003mm to ±0.005mm, with some implantable products requiring extreme precision of ±0.001mm. Geometric accuracy must meet high-precision grades under ISO 1101 standards, such as maintaining parallelism and perpendicularity errors within 0.005mm. Surface quality demands an Ra value below 0.2μm, with a requirement for defect-free and contamination-free cleanliness.

II. Technical Paths to Achieve High Precision

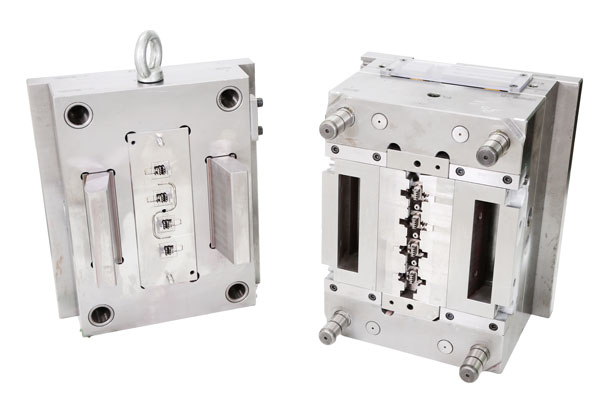

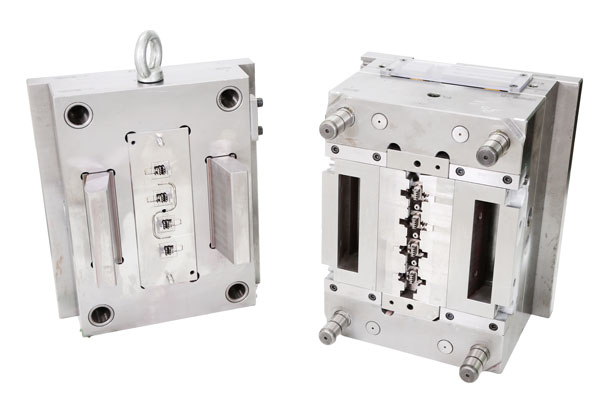

1. Ultra-Precision Mold Manufacturing Technology

Utilizing five-axis machining centers and other ultra-precision equipment, positioning accuracy can reach ±0.001mm, with repeatability accuracy better than ±0.0005mm. Through multi-axis simultaneous machining technology, micron-level machining of complex cavities is achieved. In mold inspection, real-time feedback systems of coordinate measuring machines (CMMs) enable dimensional error correction to the 0.001mm level, combined with laser interferometers for dynamic precision compensation, forming a closed-loop manufacturing system.

2. Hydrodynamic Optimization Design

The mold runner system employs computational fluid dynamics (CFD) simulation technology to optimize gate placement, runner cross-sectional areas, and melt filling paths. For thin-walled structures, multi-point gating and hot runner systems ensure uniform melt filling, avoiding dimensional deviations caused by pressure gradients. The cooling system adopts conformal cooling channel design, generating cooling paths that fully conform to the product contour through topological optimization algorithms, maintaining mold surface temperature differentials within ±1°C to eliminate thermal stress-induced deformation.

3. Synergy of Materials Science and Process Engineering

The selection of injection molding materials directly impacts precision stability. Crystalline materials (e.g., PLA) require molecular structure modification to regulate crystallinity, while amorphous materials (e.g., PEEK) necessitate optimization of carbon fiber content to balance mechanical properties with shrinkage rates. In terms of process parameters, injection pressure must be dynamically adjusted according to wall thickness, with thin-walled parts using 60-80MPa low-pressure high-speed injection and thick-walled parts requiring 100-120MPa high-pressure low-speed filling. Precise matching of holding pressure and cooling time can reduce internal defects by over 50%.

III. Technical Assurance for Precision Maintenance

1. Environmental and Equipment Control

The production environment must meet ISO 14644-1 standards, with implantable product workshops requiring ISO Class 5 (Class 100) cleanliness. Injection molding machines adopt closed-loop servo control systems, with pressure fluctuations controlled within ±0.5% and temperature control accuracy reaching ±0.5°C. Mold temperature regulation employs PID intelligent algorithms for dynamic temperature compensation.

2. Quality Traceability System

A full-process traceability system from raw materials to finished products is established, with each batch of materials requiring key parameters such as molecular weight distribution and shrinkage rate. Non-destructive testing is conducted using X-ray computed tomography (CT), combined with finite element analysis (FEA) to predict product service performance. Critical dimensions are measured using laser scanning, with data directly transmitted to the MES system for real-time monitoring.

IV. Technical Challenges and Development Trends

Current technical bottlenecks primarily focus on dimensional stability control of ultra-thin-walled structures (wall thickness <0.1mm) and the precision matching of interfaces in multi-material composite injection molding. Future development directions include AI-based adaptive optimization of process parameters, breakthroughs in precision control of metal-polymer composite injection molding technologies, and the rapid iteration capabilities of 4D-printed molds.

The precision control of medical mold injection products is a systematic endeavor, with its technical boundaries expanding through the deep integration of materials science, precision manufacturing, and intelligent control. With the development of nanoscale machining technology and in-situ monitoring technologies, the precision level of medical injection-molded parts is expected to enter the atomic-level control era, providing foundational support for the precise manufacturing of personalized medical devices.

Home

Home