In the field of medical injection molding processing, the problem of burrs is common yet cannot be ignored. This seemingly minor defect can actually have a significant impact on product quality and usage safety, becoming a key factor restricting the improvement of production efficiency and product quality. Therefore, it is crucial to promptly and effectively solve the burr problem in medical injection molding processing. The following will elaborate on effective strategies for solving this problem from multiple key dimensions.

Mold Design: Source Control, Laying the Foundation

Mold design serves as the first line of defense in reducing burr generation, playing a crucial role in source control. During the mold design stage, the edges and corners of the mold need to be carefully crafted to ensure smooth transitions, and sharp corners should be strictly avoided. Sharp corners can easily lead to poor plastic flow, thus causing burrs. At the same time, reasonable design of the feed inlet and discharge outlet is also essential. Scientifically planning the positions and sizes of the feed inlet and discharge outlet can ensure the smooth and uniform flow of plastic within the mold, effectively reducing the retention and accumulation of plastic in the mold and thus minimizing the probability of burr generation from the source.

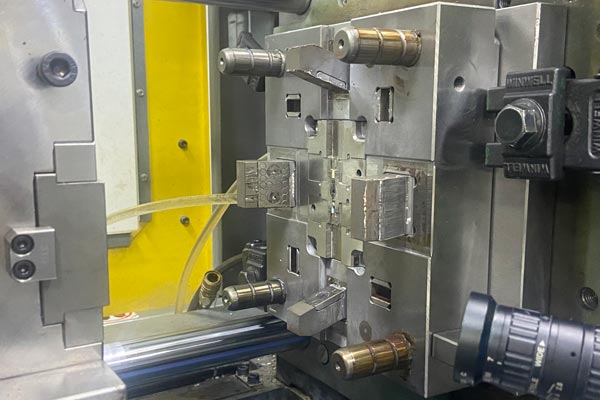

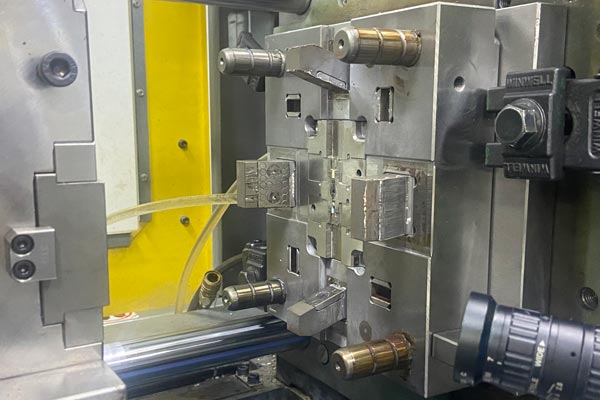

Mold Processing Accuracy: Striving for Perfection, Ensuring Quality

The processing accuracy of the mold is like the foundation of a building, directly determining the final quality of the product. To effectively reduce burr generation, it is necessary to ensure that the manufacturing and processing accuracy of the mold strictly meet the standard requirements. During the mold processing, advanced processing techniques and equipment should be used to finely process the mold surface and minimize its roughness as much as possible. The smoother the mold surface, the less resistance the plastic will encounter during flow, and the lower the likelihood of burr generation. Therefore, striving for perfection in mold processing accuracy is a key link in ensuring product quality and reducing burrs.

Injection Molding Machine Parameter Adjustment: Precise Control, Finding the Balance

The reasonable adjustment of injection molding machine parameters is an important means of solving the burr problem. Parameters such as temperature, pressure, and speed are interrelated and influence each other, jointly determining the flow state of plastic within the mold. By precisely adjusting these parameters, ensuring that the plastic can fully melt and flow uniformly within the mold is the core point to avoid burr generation. If the temperature and pressure are too high, the plastic will flow excessively and easily overflow the mold edges to form burrs; while if the temperature and pressure are too low, it may lead to insufficient plastic flow and problems such as underfilling. Therefore, operators need to find the appropriate parameter balance point through repeated experiments according to different plastic materials and mold structures to ensure the stability of the injection molding process and the consistency of product quality.

Release Agent Application: Auxiliary Support, Facilitating Demolding

The appropriate use of release agents can provide strong auxiliary support for solving the burr problem. During the injection molding process, there is often a certain amount of friction between the product and the mold, which may make it difficult for the product to be demolded and even lead to burr generation. The release agent can form a lubricating film between the product and the mold, effectively reducing the friction between the two and enabling the product to be more easily and smoothly removed from the mold. This not only reduces burrs caused by difficult demolding but also improves production efficiency and extends the service life of the mold. However, it should be noted that the use of release agents should be appropriate, as excessive use may affect the surface quality of the product.

Post-processing: Remedial Measures, Improving Quality

Although the above measures can minimize burr generation to the greatest extent, in actual production, it may still be impossible to completely avoid the appearance of burrs. For burrs that have already been generated, effective post-processing methods need to be adopted for removal. Mechanical processing is a commonly used deburring method, including operations such as grinding and polishing. By using appropriate tools and processes to finely grind and polish the burrs on the product surface, the product surface can be restored to a smooth and flat state. In addition, chemical treatment is also a viable option. Using specialized deburring agents can quickly and effectively dissolve and remove burrs, but it is necessary to choose the appropriate deburring agent and strictly follow the operating procedures to avoid damaging the product.

Quality Control and Inspection: Full-process Monitoring, Preventing Problems in Advance

Strengthening quality control and inspection during the production process is a long-term guarantee mechanism for solving the burr problem. Establish a complete quality control system and regularly inspect and maintain key equipment such as molds and injection molding machines to ensure they are always in good operating condition. During the production process, adopt advanced inspection techniques and equipment to monitor the products in real-time and promptly detect and handle any potential burr problems. Through full-process monitoring of the production process, problems can be prevented before they occur, and burr problems can be eliminated in the bud, thus ensuring the stability and reliability of product quality.

In conclusion, solving the burr problem in medical injection molding processing is a systematic project. It requires a comprehensive approach from multiple aspects such as mold design, mold processing accuracy, injection molding machine parameter adjustment, release agent application, post-processing, and quality control and inspection to form a complete solution. Only in this way can the burr problem be effectively solved, the quality and production efficiency of medical injection molding products be improved, and strong support be provided for the development of the medical industry.

Home

Home