In the field of medical device manufacturing, liquid silicone rubber (LSR) injection molding technology has become a core driving force for industry innovation, thanks to its unique material properties and precision molding capabilities. From implantable devices to in-vitro diagnostic equipment, from surgical tools to wearable medical products, LSR injection molding is reshaping the design boundaries and manufacturing standards of medical devices.

I. Material Properties: A Perfect Balance of Biocompatibility and Functionality

The molecular structure of liquid silicone rubber endows it with excellent biological safety. It has passed ISO 10993 series standards, being non-cytotoxic and non-sensitizing. It can withstand high-temperature and high-pressure sterilization (134℃/20 minutes) and is resistant to gamma radiation (25-50 kGy) and ethylene oxide (ETO) disinfection, ensuring safety in long-term implantation or repeated-use scenarios. For example, the coating layer of cardiac pacemaker leads uses LSR material. Its Shore A hardness of 30-50 and tear resistance enable it to withstand the dynamic stress generated by heartbeats while preventing inflammation caused by direct contact between the metal lead and tissues.

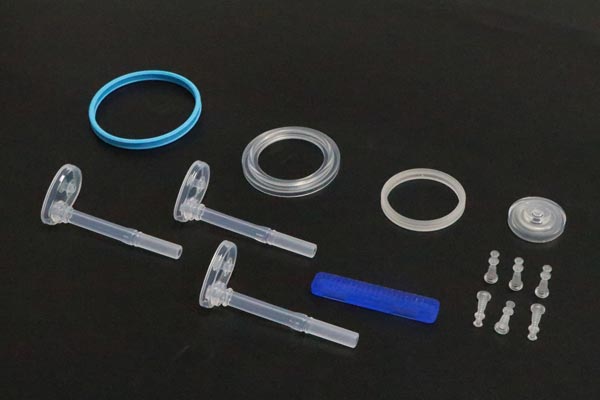

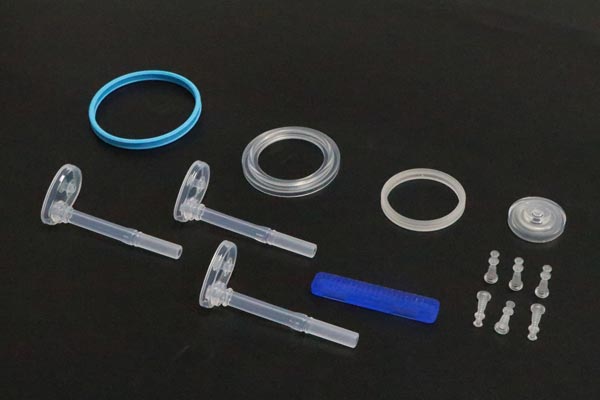

In terms of functionality, the physical properties of LSR can be precisely controlled. Its hardness range covers Shore A 10-80, meeting the needs of soft contact layers (such as CPAP mask pads) and high-strength seals (such as syringe pistons). Its low compression set (<5%) ensures that seals maintain airtightness during long-term use. Its smooth surface (Ra < 0.8μm) and antibacterial properties significantly reduce the risk of infection in catheter-type devices. Additionally, the chemical inertness of LSR allows it to withstand long-term contact with drugs. After adopting this material for insulin pump tubing, the leachable content is less than 0.1 ppm, well below FDA standards.

II. Process Breakthroughs: A Manufacturing Revolution from Single-Layer to Composite Structures

The core advantage of LSR injection molding lies in its ability to achieve "one-shot molding with multi-layer composites." Through multi-color and multi-material injection molding machines, it can achieve micron-level precision (±0.05 mm) in hard-soft structure composites. For example, vascular intervention catheters use an inner layer of PA (polyamide) for rigidity and an outer layer of LSR (Shore A 25) for a soft touch. The two are combined through secondary injection molding, and the bending fatigue test can reach over 100,000 cycles, meeting ISO 10555 standards. In the field of surgical instruments, the LSR-coated PC (polycarbonate) handle is combined with an undercut mechanical interlocking structure (depth 0.3 mm) and plasma surface treatment (surface energy increased to 60 mN/m), resulting in a bonding strength exceeding 5 N/mm², effectively solving the problem of delamination in traditional adhesive processes.

For complex geometric structures, LSR injection molding demonstrates unique advantages. The sealing ring for endoscope lenses adopts a 0.1 mm thin-wall design. Through mold flow analysis and vacuum degassing (-0.1 MPa/10 minutes), the defect rate is controlled below 0.1%. The LSR housing of cochlear implants combines 3D-printed substrates with secondary injection molding to achieve personalized customization, fitting the patient's cochlear shape and reducing signal transmission loss by 30%.

III. Application Scenarios: Innovative Practices Covering the Entire Medical Cycle

-

Implantable Devices: The LSR sealing ring of artificial heart valves has its bonding strength with the titanium alloy substrate increased by 40% through optimized vulcanization processes (vulcanization time of 15 seconds/holding pressure of 60 MPa), enabling it to withstand dynamic stress in the body for over 10 years. The filling material for breast implants uses medical-grade LSR (certified by FDA 21 CFR 177.2600). Its touch and elastic modulus (0.5-1.2 MPa) are close to those of natural tissues, reducing the postoperative complication rate to 0.3%.

-

In-Vitro Diagnostic Equipment: Blood oxygen probes use LSR-coated PCB boards. Their light transmittance (>90%) and chemical corrosion resistance (withstanding 5,000 wipes with 75% ethanol) ensure signal stability. Microfluidic chips achieve precise molding of microchannels (width 50 μm) through LSR injection molding. Combined with hydrophilic surface treatment, the sample detection time is reduced to one-fifth of that of traditional methods.

-

Surgical and Nursing Instruments: The LSR anti-slip layer (friction coefficient 0.8) on surgical scissors reduces the operating force by 20%, reducing doctor fatigue. The stop valve of infusion bags uses an LSR self-sealing structure (opening pressure 0.02 MPa), maintaining sealing performance in the range of -40℃ to 150℃ and preventing drug leakage. Baby bottle nipples use food-grade LSR (compliant with GB 4806.11-2016) with a bionic nipple design (protruding particle diameter 0.5 mm) to promote infant oral development.

IV. Future Trends: Dual Upgrades in Intelligence and Sustainability

With the development of the Internet of Medical Things (IoMT), LSR injection molding is deeply integrating with sensor technology. For example, smart orthoses embed flexible pressure sensors (thickness 0.3 mm) in the LSR contact layer to monitor the pressure distribution on the wearer in real time. The data is transmitted to a mobile app via Bluetooth, guiding patients to adjust their posture. The development of biodegradable LSR materials (such as polylactic acid-modified silicone rubber) enables temporary implantable devices (such as vascular stents) to degrade naturally after fulfilling their purpose, avoiding secondary surgery risks.

On the manufacturing side, Industry 4.0 technologies are reshaping LSR injection molding production lines. After introducing an MES system, a company has reduced the product defect rate from 2% to 0.3% by real-time monitoring of parameters such as mold temperature (precision ±0.5℃) and injection pressure (precision ±0.1 MPa). It also achieves rapid switching for multi-variety and small-batch production (mold change time <10 minutes). In addition, the application of water-based mold release agents and closed-loop cooling systems has reduced the energy consumption of a single machine by 15%, in line with green manufacturing trends.

Conclusion

Liquid silicone rubber injection molding technology is redefining the manufacturing standards of medical devices through material innovation, process breakthroughs, and application expansion. From microstructure precision control to macro-system intelligent integration, from short-term contact consumables to long-term implantable devices, every evolution of LSR technology is pushing the medical industry toward a safer, more efficient, and more personalized direction. In the future, with the deep integration of material science and digital technology, this "hidden champion" technology will undoubtedly create more possibilities for human health.

Home

Home