I. Material Factors: Compatibility Imbalance and Contamination Risks

1.1 Compatibility Conflicts in Multi-Component Materials

Medical products often use blended modified materials (e.g., PC/ABS for housings, PEEK/carbon fiber for orthopedic implants). Insufficient compatibility agents or incorrect formulations can lead to interfacial tension differences, causing layer separation. For instance, a company producing dialysis machine housings experienced a 12% recall rate due to improper PC/ABS ratios and inadequate compatibility agents, resulting in "mica-like" peeling on product surfaces.

Solutions:

-

Strictly adhere to material supplier-recommended blend ratios and compatibility agent types (e.g., SMA resins for PC/ABS systems).

-

Sort and test recycled materials for compatibility to avoid mixing different grades or types of plastics.

1.2 Catalytic Effects of Moisture and Contamination

Medical-grade plastics (e.g., PPSU for baby bottle components, POM for surgical instrument handles) are moisture-sensitive. Inadequate drying (residual moisture >0.02%) causes vaporization, forming bubbles that disrupt melt fusion. A medical device manufacturer producing infusion pump housings encountered 0.5mm-thick peeling layers due to oil contamination from improperly cleaned recycled materials.

Solutions:

-

Use dehumidifying dryers (dew point ≤-40°C) and extend drying time by 20 minutes per millimeter of material thickness.

-

Add raw material filtration (e.g., 80-mesh screens for recycled materials).

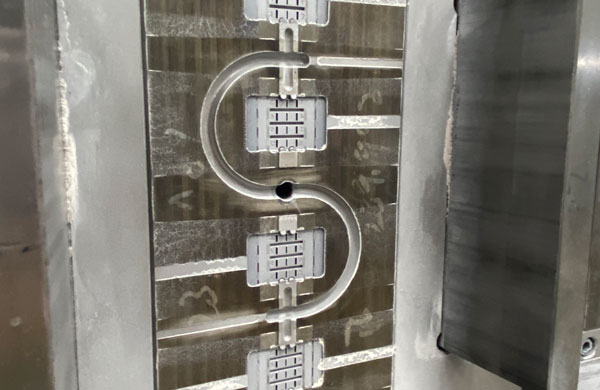

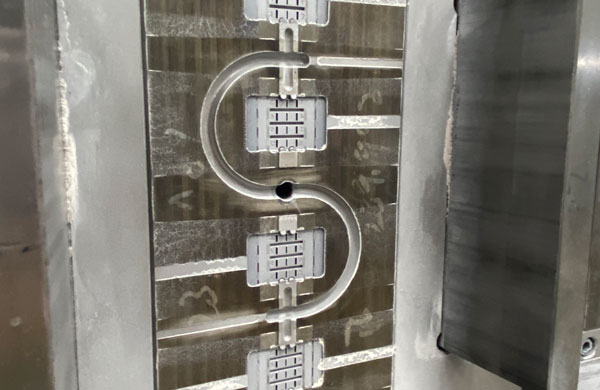

II. Mold Design: Runner and Venting Defects

2.1 Shear Traps in Runner Systems

Sharp corners in medical product molds (e.g., 90° angles) can increase shear rates to 10⁴ s⁻¹, raising local temperatures by over 30°C and causing material degradation. A company producing endoscope tip housings faced an 8% scrap rate due to 0.2mm-deep delamination cracks caused by sharp runner ends.

Optimization Strategies:

-

Use R≥5mm rounded transitions in runner corners to reduce shear stress by >30%.

-

Design gate sizes proportionally to product wall thickness (e.g., gate diameter ≥0.8t for thin-walled parts).

2.2 Venting System Failures

Improper venting (e.g., vent slots >0.03mm deep or misplaced) traps gases, forming high-pressure films that hinder melt fusion. A manufacturer of hearing aid housings achieved only 65% yield due to 2mm-diameter peeling spots from poor parting-line venting.

Improvement Measures:

-

Install 0.01–0.02mm-deep vent slots at melt convergence points and core tips.

-

Adopt vacuum venting systems (residual pressure <50mbar) to improve gas evacuation efficiency by 90%.

III. Process Parameters: The Art of Balancing Temperature and Pressure

3.1 The Double-Edged Sword of Temperature Control

Medical injection molding is highly temperature-sensitive:

-

Low barrel temperatures (e.g., PA66 barrel <260°C): Increased melt viscosity reduces interlayer shear, causing poor fusion. A company producing blood glucose meter housings encountered 0.1mm-thick peeling layers due to a 15°C temperature deviation in barrel zone three.

-

High mold temperatures (e.g., PEEK mold >180°C): Prolonged cooling times increase residual stress, leading to peeling. An orthopedic implant manufacturer observed 0.3mm-deep delamination after three months of storage due to excessive mold temperatures.

Precision Control Solutions:

-

Segment barrel temperatures (e.g., PC: 220°C in zone one, 250°C in zone two, 280°C in zone three).

-

Use mold temperature controllers to maintain stability (e.g., 120±2°C for medical silicone products).

3.2 Multi-Stage Injection Speed Management

Medical products require staged injection speed control:

-

First-stage high speed (80–90%): Rapid cavity filling reduces melt front cooling.

-

Second-stage low speed (30–50%): Reduces shear stress near gates to prevent degradation. A manufacturer of syringe pistons faced 0.2mm-deep circumferential peeling due to excessive end-of-injection speeds (>100mm/s).

Optimized Parameters:

-

Set injection speeds at 50–80mm/s for thin-walled parts and 30–50mm/s for thick-walled parts.

-

Adjust packing pressure based on wall thickness (e.g., 70% of injection pressure for 1.5mm-thick products).

IV. Equipment Conditions: The Cascading Effects of Hidden Failures

4.1 Screw Wear and Plasticization Crises

Screw wear exceeding 0.3mm reduces plasticization capacity by >20%, causing ±5°C melt temperature fluctuations. A company producing ventilator masks encountered 0.15mm-thick peeling layers and a 15% increase in customer complaints due to screw wear.

Maintenance Strategies:

-

Inspect screw clearance every 500,000 cycles and replace worn components.

-

Regularly clean residual medical-grade lubricants (e.g., polytetrafluoroethylene micropowders) from screw barrels.

4.2 Heating System Uniformity Defects

Temperature deviations >±3°C in barrel heating zones create 50% viscosity differences in local melts. A manufacturer of infusion set connectors faced 0.1mm-deep peeling lines and a 10% rework rate due to heating coil failures.

Solutions:

-

Install infrared thermometers for real-time barrel temperature monitoring.

-

Adopt zone-controlled heating systems with independent PID regulation.

V. Special Requirements in the Medical Industry: Validation and Traceability

Medical products must comply with ISO 13485 and FDA 21 CFR 820, requiring delamination risks to be integrated into risk management systems:

-

Process Validation: Conduct PPK≥1.67 process capability analyses for critical parameters (e.g., barrel temperature, packing time).

-

Traceability Systems: Establish batch-process parameter-product serial number correlations. For example, a company reduced delamination issue identification time from 72 to 2 hours using a scanning traceability system.

Conclusion

Delamination and peeling in medical injection-molded products result from interactions among materials, molds, processes, and equipment. Implementing compatibility management, runner optimization, temperature-graded control, and preventive equipment maintenance can reduce peeling rates from an industry average of 3–5% to below 0.5%. As medical injection molding advances toward higher precision and multifunctionality, AI-driven process optimization systems (e.g., melt flow simulation and defect prediction) will emerge as new solutions for delamination issues.

Home

Home