Injection molding of medical products, due to its stringent requirements for precision, biocompatibility, and reliability, has become a core part of high-end manufacturing. As the "heart" of the injection molding process, mold design directly affects product yield, production costs, and clinical safety. This article systematically elaborates on the core strategies for medical mold design from four dimensions: classified design, material selection, process optimization, and intelligent control, combined with the latest technological trends in the medical industry.

1. Classified Design of Molds Based on Clinical Scenarios

Medical molds need to be designed according to different product applications with differentiated design standards, mainly divided into three categories:

-

Molds for Disposable Medical Consumables

Take syringes and infusion sets as examples. The core requirements are high production capacity and low deviation. For instance, the cavity spacing error of an 8-cavity syringe mold should be controlled within ±0.03mm, and the inner diameter tolerance of the barrel should be ≤ ±0.02mm to ensure accurate dosage. The drip chamber mold of an infusion set requires ultra-precision polishing technology (Ra ≤ 0.05μm) to prevent liquid from adhering to the walls. The parting surface of the connector mold should be designed with a sealing structure, and the leakage rate should be less than 0.01mL/min under a pressure of 1MPa.

-

Molds for Implantable Medical Devices

For orthopedic implants (such as artificial joints), the mold requires five-axis simultaneous machining, with a positioning accuracy of the mold core reaching ±0.001mm. After nitriding treatment (hardness ≥ HV850), the surface is mirror-polished to Ra ≤ 0.01μm to ensure a fit error of ≤0.05mm with bone tissue. For cardiovascular stent molds, micro-electrical discharge machining technology is needed. The minimum cavity wire diameter is only 0.1mm with a tolerance of ±0.005mm to ensure the dimensional consistency of the stent after expansion.

-

Molds for In Vitro Diagnostic Consumables

The cavity depth tolerance of test strip molds should be ≤ ±0.01mm to control the coating thickness deviation within 5%. The sampling swab mold adopts a two-color injection molding structure. The texture design of the head flocking cavity needs to precisely control the flocking density (300 roots/mm²) and the shedding rate (≤0.1%), and the connection strength between the head and the rod should be ≥50N.

2. Material Selection and Surface Treatment Technologies

-

Materials for Biological Contact Components

S136 stainless steel is preferred. After solution treatment at 1050℃ and aging treatment at 450℃, its hardness reaches HRC45-48, complying with ISO 10993-1 standards and able to withstand 20 cycles of high-temperature sterilization at 121℃ without rusting. For scenarios with high wear resistance requirements (such as reagent bottle molds), 718H pre-hardened steel (HRC32-36) can be used, with a wear amount of ≤0.002mm after 100,000 injection molding cycles.

-

Innovative Surface Treatments

The surface of implantable device molds needs to reduce the friction coefficient through PVD coating technology while improving fatigue resistance through nitriding treatment. For example, after gas nitriding, the surface hardness of orthopedic implant molds can be increased to above HV1000, extending the service life by 40%. For transparent medical components (such as light guides), S136 fully hardened stainless steel should be used along with precision polishing to ensure a light transmittance of ≥92%.

3. Precision Machining and Process Optimization Strategies

-

Multi-cavity and Microstructure Machining

Using ultra-precision five-axis simultaneous machining centers with a positioning accuracy of ±0.001mm enables the design of more than 64 cavities. For example, by introducing German imported technology, a company has controlled the cavity size tolerance of microfluidic chip molds within ±0.003mm, increasing the daily production capacity of a single mold by 300%.

-

Conformal Cooling System Design

For complex curved medical components (such as cochlear implant shells), 3D printing technology is used to build conformal cooling channels, keeping the mold surface temperature difference within ±1℃, improving the cooling efficiency by 35%, and reducing the product warpage rate to below 0.2%.

-

Intelligent Control of Injection Molding Process Parameters

Through a combination of experiments and simulations, a process parameter database is established. For example, in the production of polycarbonate (PC) cardiac stents, the barrel temperature needs to be precisely controlled between 280-320℃, the mold temperature between 80-120℃, the injection pressure between 60-80MPa, and the injection speed between 30-50mm/s to avoid rupture in thin-walled areas. An Internet of Things mold management system deployed by a company can monitor temperature and pressure parameters in real-time, reducing the scrap rate from 5% to 0.8%.

4. Intelligence and Full-process Control

-

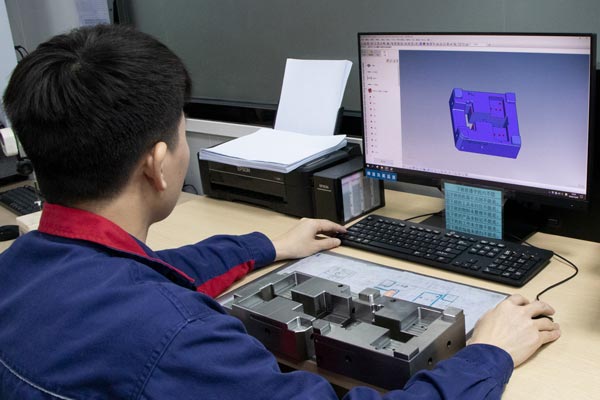

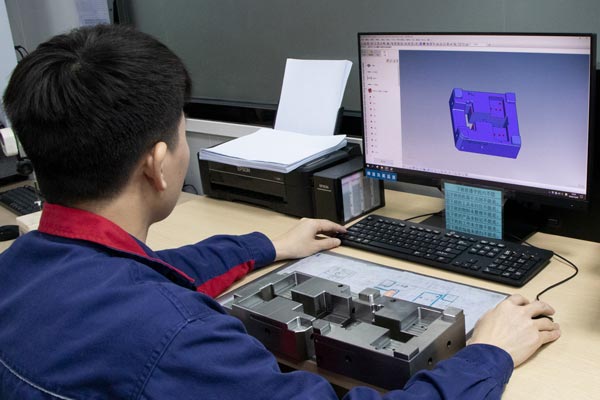

Digital Twin Technology

A virtual debugging model of the mold is constructed, and CAE analysis is used to predict the melt filling and cooling processes, reducing the number of mold trials. After applying this technology, a company has reduced mold trial costs by 30% and shortened the development cycle by 20%.

-

Predictive Maintenance System

Sensors are embedded in the mold to monitor abnormalities such as mold core wear and cooling channel blockage in real-time. For example, on an orthopedic implant production line, this system has reduced unexpected mold downtime by 65% and annual maintenance costs by 2 million yuan.

-

Standardized and Modular Design

Promote the use of universal mold bases and standard parts (accounting for ≥70%) to shorten the design cycle. For small-batch production, 1-2 cavity molds are used; for large-batch production, molds with more than 64 cavities are selected to balance mold costs and production efficiency.

5. Future Trends and Challenges

With the development of minimally invasive medical and in vitro diagnostic technologies, molds will be upgraded in the following directions:

-

Nanoscale Precision: Achieve nanoscale modification of the mold cavity surface through atomic layer deposition (ALD) technology to improve biocompatibility.

-

Compatibility with Biodegradable Materials: Develop molds suitable for biodegradable materials such as polylactic acid (PLA) to control the degradation rate to match the product lifespan.

-

AI-driven Process Optimization: Use machine learning to analyze historical production data and automatically generate the optimal combination of process parameters, achieving "lights-out factory" production.

Conclusion

Medical mold design is a cross-disciplinary systematic project that requires the integration of multiple fields such as materials science, precision machining, and intelligent control. Through classified design, material innovation, process optimization, and intelligent control, the service life of molds and product yield can be significantly improved, driving the Chinese medical injection molding industry towards high-end and international development. In the future, with the in-depth integration of nanotechnology, additive manufacturing, and AI technology, medical molds will usher in a new round of technological revolution, providing more precise and reliable manufacturing solutions for global medical and health undertakings.

Home

Home