In the medical field, injection molding processing, as a key technology, plays a pivotal role. It is like a precisely assembled jigsaw puzzle, with each piece closely connected and indispensable, jointly building the foundation for high-quality medical products. So, what aspects should be paid attention to in medical injection molding processing? The core points mainly cover the following key dimensions.

1. Raw Material Selection: Laying the Foundation of Safety

Raw material selection is the first crucial step in medical injection molding processing. Medical products are closely related to patients' lives and health, so their raw materials must undergo strict screening and meet stringent medical standards. Biocompatibility ensures that the materials do not cause adverse reactions when in contact with human tissues and blood. Non-toxicity guarantees that no harmful substances are released during normal use, protecting human health. Non-allergenicity prevents allergic reactions, providing safety for patients. Among numerous raw materials, polyolefins, polyurethanes, and polycarbonates are commonly used in medical injection molding processing due to their excellent properties.

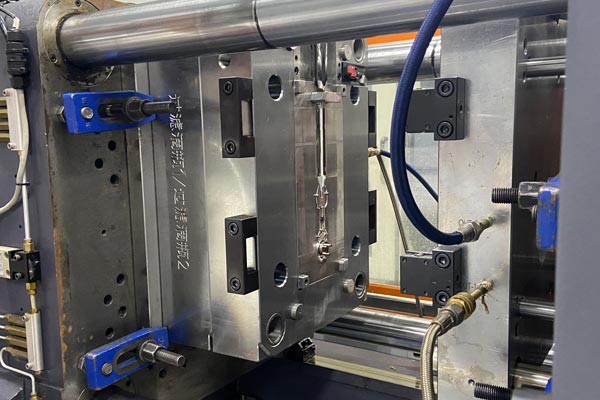

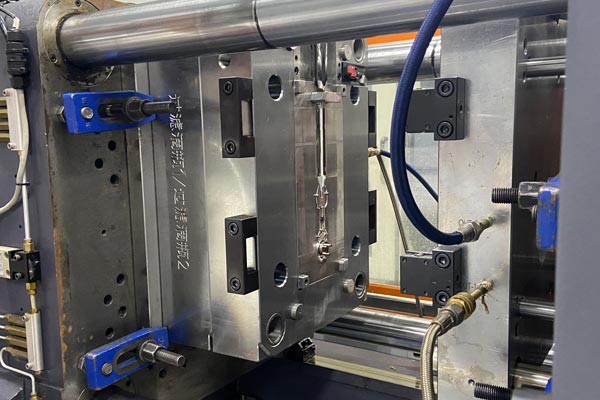

2. Injection Molding Machine Selection: Controlling the Core Power

The injection molding machine, as the core equipment in medical injection molding processing, is like the "heart" of the entire process, and its performance and quality directly determine the quality and production efficiency of the products. It mainly consists of key parts such as the injection system, clamping system, and control system. The injection system, like a precise "syringe," can accurately control parameters such as injection pressure, speed, and temperature, ensuring that the raw materials are evenly and stably injected into the mold. The clamping system acts as a sturdy "guardian," ensuring that the mold remains tightly closed during the injection process to prevent raw material leakage. The control system, like an intelligent "brain," monitors and precisely regulates the entire injection process in real-time, ensuring the stability and consistency of the products.

3. Mold Design: Carving Exquisite Appearances

Molds play an indispensable role in medical injection molding processing, acting like a highly skilled "sculptor" that directly determines the appearance and performance of the products. Mold design is not just about simple drawing and manufacturing but an integrated art. When designing, it is necessary to fully consider key factors such as the shape, size, and wall thickness of the products to ensure that they can be perfectly formed. At the same time, it is also essential to combine process parameters such as injection pressure and temperature for scientific and reasonable layout and optimization, enabling the mold to withstand various complex forces during the injection process and ensuring stable product quality.

4. Process Control: Ensuring Consistent Quality

Production process is a key link in medical injection molding processing, resembling a precise assembly line where each step is closely connected and interdependent. Starting from raw material preparation, strict checks on the quality and batch of the raw materials are required to ensure they meet production requirements. During the mold preparation stage, the mold needs to be cleaned, debugged, and preheated to ensure it is in the best working condition. Process control during the injection process is of utmost importance. It is necessary to strictly control parameters such as injection pressure, speed, and temperature, as well as process conditions such as cooling time and holding pressure time, ensuring that the products are evenly filled and rapidly cooled during the injection process, thus obtaining the ideal appearance and performance.

5. Quality Inspection: Building a Safety Barrier

Quality inspection is the last line of defense in medical injection molding processing and a key step to ensure that product quality meets medical standards and user requirements. Through strict inspection procedures, a comprehensive and detailed check is carried out on aspects such as the appearance quality, dimensional accuracy, and physical properties of the products. Appearance quality inspection mainly checks whether the product surface is smooth, free of defects, and has uniform color. Dimensional accuracy inspection uses precise measuring tools to ensure that the product dimensions meet the design requirements. Physical property inspection tests the strength, hardness, and toughness of the products to ensure that they can withstand various external forces during actual use without damage or deformation.

Medical injection molding processing is a complex and rigorous process. From raw material selection to quality inspection, every link requires strict control. Only by paying comprehensive and multi-dimensional attention to these key elements can high-quality and high-performance medical products be created to safeguard patients' health.

Home

Home