In the global medical device manufacturing sector, polyphenylsulfone (PPSU), a high-performance thermoplastic engineering plastic, is reshaping the design and production standards of medical devices with its unique physicochemical properties. This material has broken through the limitations of conventional plastics in terms of high-temperature and chemical corrosion resistance. Moreover, through precision injection molding processes, it has enabled the lightweight, functional, and long-lasting design of medical devices, becoming an indispensable strategic material in modern medical industry.

I. Material Properties: An All-Round Player in Medical Scenarios

The molecular structure of PPSU endows it with extreme environmental adaptability that surpasses ordinary plastics. Its glass transition temperature reaches 150°C, with a continuous operating temperature range spanning from -100°C to 180°C and a heat deflection temperature as high as 207°C. It can withstand over 1,000 cycles of high-pressure steam sterilization at 121°C - 134°C without performance degradation. This characteristic makes it the material of choice for surgical instruments and endoscope components that require repeated sterilization. For example, after injection molding, the handles of surgical forceps can maintain dimensional stability after thousands of high-temperature sterilization cycles, ensuring operational precision.

In terms of chemical stability, PPSU exhibits excellent resistance to medical disinfectants such as alcohol, hydrogen peroxide, and strong alkalis. Laboratory data shows that its tensile strength retention rate remains at 98% after 72 hours of exposure to a 10% sodium hypochlorite solution. This property makes it widely applicable in scenarios such as dialysis equipment housings and respiratory masks that require frequent chemical cleaning.

Biocompatibility is the cornerstone of PPSU's medical applications. This material has passed multiple international medical certifications, including ISO 10993, USP Class VI, and FDA CFR 21, and is free from harmful substances such as bisphenol A (BPA) and plasticizers. In hemodialysis systems, PPSU tubing connectors have been verified through long-term clinical trials to have no leachate exceeding standards or tissue irritation reactions, ensuring patient safety.

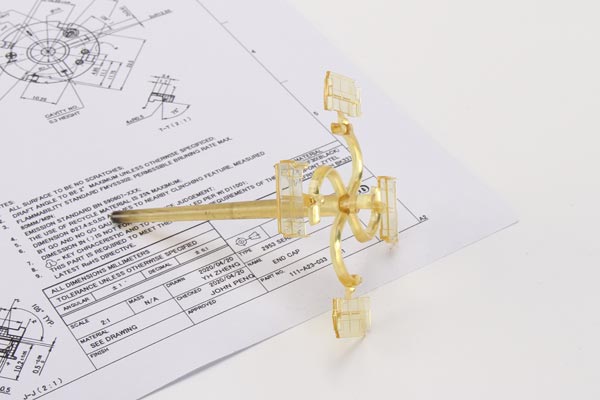

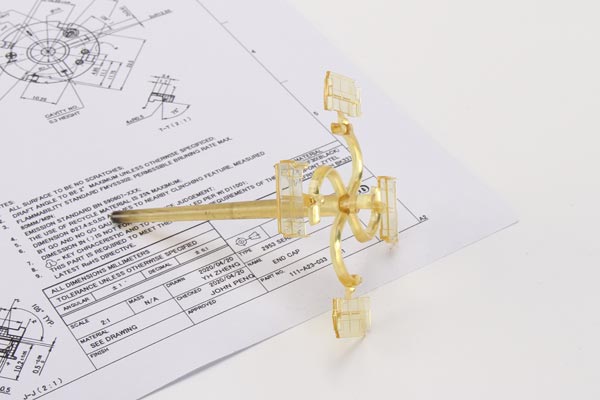

II. Precision Injection Molding: Process Breakthroughs from Molecules to Devices

The injection molding of PPSU requires precise control of three core parameters: drying treatment (90°C - 110°C for 3 - 4 hours), melting temperature (260°C - 280°C), and mold temperature (80°C - 100°C). By employing multi-stage injection speed control (30% - 50% of the initial speed for filling and 10% - 20% of the second-stage speed for packing), dimensional accuracies of 0.02 mm and surface finishes of Ra0.2 μm can be achieved. This level of process precision enables PPSU to manufacture components with stringent tolerance requirements, such as MRI device insulation fittings and heart valve fixation brackets.

In terms of structural complexity, PPSU injection molding has surpassed the limitations of traditional metal processing. For example, endoscope housings adopt thin-wall designs (wall thicknesses of 0.8 mm - 1.2 mm) and achieve hollow structures through gas-assisted injection molding, reducing weight while maintaining impact resistance. The streamlined curved surfaces of dental high-speed drill handles eliminate weld line defects through 3D simulation-optimized gate positions, ensuring operational comfort.

Cost-effectiveness is another major advantage of PPSU injection molding. Compared with traditional stainless steel components, PPSU parts are 60% lighter, consume 45% less processing energy, and require no secondary processing such as polishing. Data from a surgical instrument manufacturer shows that adopting PPSU reduces the unit cost by 32% while decreasing the rework rate due to sterilization failures from 8% to 0.5%.

III. Typical Applications: Solutions Covering All Medical Scenarios

1. Surgical Instrument Systems

In the field of minimally invasive surgery, PPSU has become the standard material for instrument handles. Its combination of high rigidity (flexural modulus of 2.5 GPa) and low density (1.24 g/cm³) allows laparoscopic forceps bodies to maintain operational stability even when extended to 45 cm in length. After adopting a PPSU/glass fiber composite material, the vibration attenuation rate of an ultrasonic scalpel handle decreased by 28%, significantly improving surgical precision.

2. Medical Imaging Equipment

The detector brackets of CT scanners, made through PPSU injection molding, exhibit a dimensional change rate of only 0.03% under temperature variations from -20°C to 60°C, ensuring X-ray reception accuracy. The insulating fixtures of MRI devices leverage PPSU's dielectric strength (20 kV/mm) and low magnetic permeability to effectively shield strong magnetic field interference and guarantee imaging quality.

3. Dialysis and Fluid Systems

After adopting PPSU, the housings of hemodialyzers have seen a threefold increase in chemical corrosion resistance, capable of withstanding continuous immersion in sodium hypochlorite for 30 days without cracking. Their transparency (light transmittance of 89%) facilitates the observation of blood flow by medical staff, providing 15% greater visual clarity compared to traditional polycarbonate (PC) materials.

4. Emergency and Protective Equipment

During the COVID-19 pandemic, PPSU films were used to manufacture reusable protective face shields. Their impact strength (690 kJ/m²) enables them to withstand the physical stresses during disinfection processes, while their chemical resistance ensures no micro-cracks form after ethanol wiping. A medical company reported that adopting PPSU face shields increased the usage per unit from 15 times to 200 times, significantly reducing medical waste generation.

IV. Industry Trends: The Technological Frontier of Medical Plasticization

The global market for medical-grade PPSU is growing at an annual rate of 8.3%, with an expected market size exceeding $1.2 billion by 2030. International giants such as BASF and Solvay have developed enhanced PPSU grades through molecular design. For example, adding nano-silica increases the heat deflection temperature to 220°C and reduces the friction coefficient by 40%, enabling applications in high-end fields such as temporary fixation brackets for orthopedic implants.

In the Chinese market, local companies like Shandong Haoran Special Plastics have developed medical-grade PPSU specialty materials through industry-university-research collaborations. Their melt flow rate (MFR) has been optimized from 8 g/10 min to 15 g/10 min, making it more suitable for precision injection molding. A domestic CT machine manufacturer reported a 22% reduction in detector bracket costs and a 40%缩短 (shortened) delivery cycle after adopting domestically produced PPSU.

With the integration of 3D printing technology and PPSU injection molding, the manufacturing of personalized medical devices has entered a new stage. Photocurable PPSU filaments have been used to produce customized orthoses with a printing accuracy of 0.1 mm, reducing the production cycle by 70% compared to traditional mold manufacturing. This technological transformation is driving medical devices from standardization toward precision.

Conclusion: A Material Revolution Reshaping the Future of Healthcare

The application of PPSU in medical injection molding is essentially a precise response from material science to medical needs. From precision instruments in operating rooms to giant equipment in imaging departments, and from emergency protective gear to portable home care devices, this high-performance plastic is driving the medical industry toward greater safety, efficiency, and sustainability at the molecular level. With breakthroughs in material modification technologies and advancements in processing techniques, PPSU is expected to open up new frontiers in cutting-edge fields such as biodegradable medical devices and intelligent sensing integration, continuing to lead the evolution of medical materials.

Home

Home