Medical injection-molded products, widely used in surgical instruments, implants, and diagnostic devices, demand high precision, cleanliness, and biocompatibility. However, incomplete filling (short shot)—a common defect where molten plastic fails to fully fill the mold cavity—can compromise product strength, sealing performance, and functionality, directly threatening patient safety. This article systematically explores causes, solutions, and preventive measures for incomplete filling in medical injection molding.

1. Causes of Incomplete Filling

Incomplete filling typically stems from four key factors:

1.1 Material Issues

-

Poor flowability: Medical-grade materials (e.g., PPSU, PEEK) often exhibit high viscosity, hindering filling in complex geometries.

-

Insufficient drying: Excess moisture causes material degradation, reducing flowability.

-

High recycled material content: Regrind lowers flowability and may violate medical standards (e.g., ISO 13485 limits regrind to ≤25%).

1.2 Process Parameter Errors

-

Low injection pressure: Inadequate pressure fails to overcome mold resistance.

-

Slow injection speed: Premature cooling reduces melt mobility.

-

Low melt temperature: Insufficient heat increases viscosity.

-

Inadequate packing pressure/time: Poor packing leads to shrinkage voids.

1.3 Mold Design Flaws

-

Poor runner system design: Long runners or small cross-sections cause pressure drops.

-

Improper gate placement: Few or misplaced gates disrupt melt distribution.

-

Ineffective venting: Trapped air creates backpressure, blocking flow.

-

Uneven wall thickness: Thin sections cool rapidly, halting melt advance.

1.4 Equipment Problems

-

Low clamping force: Mold leakage reduces injection pressure.

-

Poor screw design: Inadequate metering/compression ratios affect plasticization.

-

Hydraulic system instability: Pressure/flow fluctuations disrupt injection.

2. Systematic Solutions

Addressing incomplete filling requires multi-faceted optimization:

2.1 Material Optimization

-

Select high-flow medical-grade materials (e.g., modified PPSU, LCP) with lubricants/nano-fillers.

-

Strictly control drying (e.g., PEEK: 150°C for 4 hours).

-

Limit regrind use per medical regulations.

2.2 Process Adjustments

-

Increase injection pressure/speed: Use multi-stage injection (high-speed filling + low-speed packing).

-

Optimize melt temperature: Base settings on MFR tests (e.g., PEEK: 380–420°C).

-

Extend packing time: Set to 30–50% of cooling time.

-

Apply backpressure: 5–15 MPa to enhance plasticization uniformity.

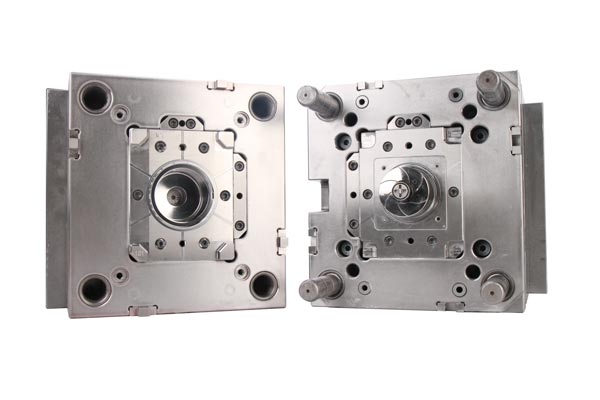

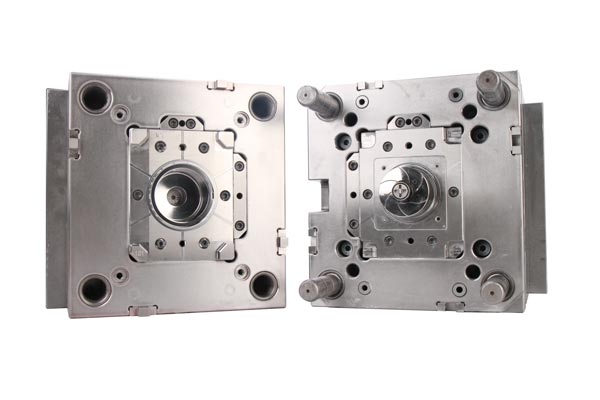

2.3 Mold Design Improvements

-

Upgrade runner systems: Use hot runners to minimize pressure loss; design cross-sections at 0.6–0.8× product wall thickness.

-

Optimize gate placement: Use Moldflow simulations to determine ideal gate count/location.

-

Add venting slots: 0.02–0.05 mm deep at parting lines/core edges.

-

Uniform wall thickness: Adjust via CAE analysis (minimum ≥0.8 mm).

2.4 Equipment Maintenance

-

Calibrate injectors (pressure/temperature sensors).

-

Upgrade screws (high compression ratios, e.g., 2.5:1–3:1).

-

Install closed-loop controls for real-time parameter adjustments.

3. Preventive Measures & Quality Management

-

Standardize SOPs: Define material preprocessing, parameter settings, and mold maintenance.

-

Implement CPK analysis: Monitor key parameters (e.g., injection pressure) for process stability.

-

Deploy online inspection: Use infrared thermometers/pressure sensors for real-time monitoring.

-

Enhance training: Regular workshops on injection molding, mold care, and medical regulations.

-

Establish traceability: Record batch-specific parameters via MES systems.

4. Case Study: Resolving Defects in Medical Catheters

A manufacturer faced incomplete filling in infusion catheters due to:

-

Root causes: Excessive runner length (30% pressure loss), inadequate drying (0.3% moisture).

-

Solutions:

-

Shortened runners by 20%, added 3 gates.

-

Adjusted drying to 120°C/6 hours (0.02% moisture).

-

Raised injection pressure to 120 MPa and speed to 80 mm/s.

-

Outcome: Filling completeness improved from 85% to 99.8%, with a 15% yield increase.

5. Conclusion

Resolving incomplete filling in medical injection molding requires a holistic approach combining material selection, process optimization, mold redesign, and equipment maintenance, supported by rigorous quality management. Future advancements in smart injection technologies (e.g., AI-driven optimization, IoT monitoring) will further enhance precision and reliability, ensuring safer medical devices.

Home

Home