Precision medical injection molding, as the core process in medical device manufacturing, directly determines the life safety and treatment efficacy of patients. From pacemaker housings to minimally invasive surgical instruments, from medical catheters to biosensor bases, every precision injection-molded part must meet stringent standards in terms of dimensional accuracy, surface quality, and biocompatibility. However, in actual production, multiple factors interact, potentially leading to dimensional deviations, surface defects, or even biocompatibility risks in products. This article systematically analyzes the key factors influencing precision medical injection molding from four dimensions: material characteristics, mold design, process control, and environmental management.

1. Material Characteristics: The Dual Challenge of Biocompatibility and Processing Stability

Medical injection molding materials must simultaneously satisfy requirements for biocompatibility, chemical stability, and processing performance. Taking polycarbonate (PC) as an example, when used to manufacture rigid oxygen masks, the material purity must be ≥99.5%, with heavy metal content <0.1 ppm to avoid releasing harmful substances during human contact. However, batch-to-batch variations in molecular weight distribution of materials can lead to shrinkage rate fluctuations of 0.2%-0.5%, directly causing product dimensional deviations. For instance, when a company producing cardiac stent delivery system components switched material suppliers and altered additive formulations, the shrinkage rate increased from 0.6% to 0.8%, resulting in product wall thickness tolerances exceeding ±0.01 mm, the medical standard.

The modification of engineering plastics also requires caution. Glass fiber-reinforced polyamide (PA+GF30%) enhances tensile strength to 180 MPa, but differences in fiber orientation can cause anisotropic shrinkage, leading to 0.1 mm-level deformations in complex structural parts. Additionally, biodegradable materials like polylactic acid (PLA) require strict temperature control during injection molding. If the barrel temperature exceeds 220°C, material degradation generates acidic substances that may corrode mold cavities while reducing product mechanical properties.

2. Mold Design: The Struggle Between Micron-Level Precision and Thermal Balance Control

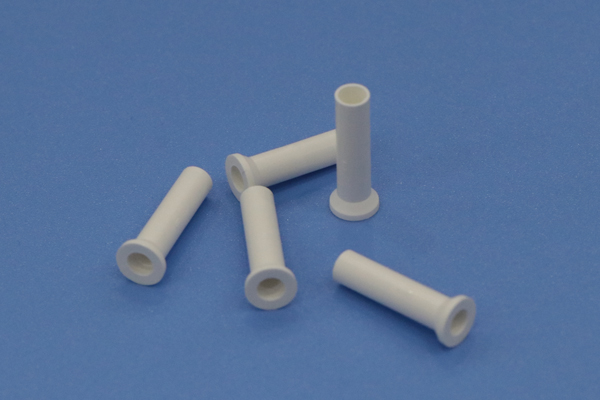

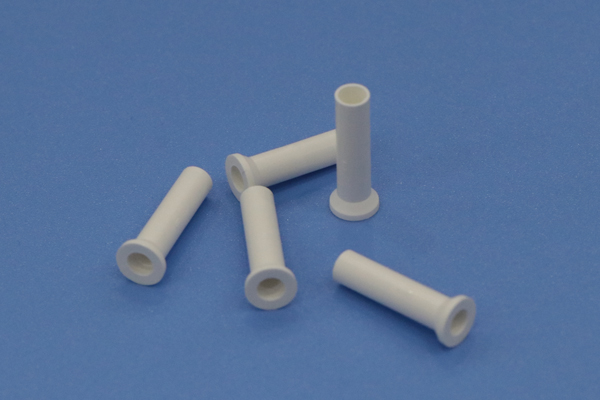

Mold precision is the core determinant of product dimensional tolerances. Medical-grade molds must use S136 fully hardened stainless steel, with cavity surface roughness reaching Ra0.05 μm or below after ultra-precision five-axis machining. For example, the mold core diameter tolerance for insulin pen needle holders must be controlled within ±0.003 mm, equivalent to 1/20th the diameter of a human hair. If pre-hardened steel is used, wear on parting surfaces after long-term production may increase flash thickness by 0.02 mm, causing assembly difficulties.

Cooling system design directly impacts product stress distribution. A company producing blood dialyzer housings experienced a 15°C/s cooling rate difference between thick and thin wall sections due to improper mold cooling water channel layout, resulting in 30 MPa residual stress and 0.3 mm warping during sterilization. By optimizing water channel arrangement and adopting conformal cooling technology, cooling uniformity improved by 40%, reducing residual stress to below 10 MPa.

Gate design must balance melt filling and weld line control. For transparent blood collection tubes and other cosmetic parts, submarine gates can relocate weld lines to non-visible areas. Meanwhile, mold flow analysis software optimizes gate quantity and position to ensure melt front convergence angles exceed 135°, significantly reducing weld line strength loss. One company improved drop test pass rates for blood collection tubes from 78% to 99% through such modifications.

3. Process Control: Precision Balancing of Multi-Parameter Collaboration

Injection temperature requires precise adjustment based on material characteristics. Polyether ether ketone (PEEK) has a narrow processing window, demanding barrel temperature stability at 380±5°C. Temperature fluctuations exceeding 10°C cause viscosity changes that may lead to 2% product weight variation and dimensional deviations. Linking infrared thermometers with PID control systems reduces temperature fluctuations to ±2°C, improving product weight consistency to ±0.5%.

Injection speed and pressure curve design influence product internal structure. For thin-walled minimally invasive surgical instrument handles, a multi-stage injection process is used: 80% speed for runner filling, 50% speed for cavity filling, and 30% speed for packing and holding. One company reduced sink mark rates from 12% to 2% and achieved 100% airtightness test pass rates through such optimizations.

Packing pressure and duration must precisely match the cooling process. In PPSU surgical knife handle production, insufficient packing pressure (<80 MPa) or short duration (<3 s) increases shrinkage by 0.15%, causing assembly clearance deviations with metal components. Design of Experiments (DOE) methods optimized process parameters, achieving ±0.01 mm dimensional stability that meets FDA standards.

4. Environmental Management: The Invisible Defense Line of Cleanliness and Static Control

Medical injection molding workshops must maintain ISO Class 7 (10,000-grade) cleanliness, with airborne particle concentrations ≥0.5 μm <352,000 particles/m³. A company producing cardiac valve stents faced thrombosis risks due to 0.3 μm particle adhesion on product surfaces caused by insufficient workshop cleanliness. Upgrading to FFU fan filter units and positive pressure control systems improved cleanliness to ISO Class 5 (100-grade), reducing defect rates from 1.2% to 0.05%.

Static control is critical for micro-component production. In syringe piston head manufacturing, ambient humidity <40% causes static adhesion, leading to 0.5 mg weight deviations that affect sealing performance. Installing ionizing blowers and humidity regulation systems (maintaining 50%±5% RH) improved product weight consistency to ±0.1 mg.

Conclusion: Full-Process Control Builds Quality Defenses

Quality control in precision medical injection molding must span the entire lifecycle from material selection to mold design, process optimization, and environmental management. A leading company achieved a product dimensional CPK value increase from 1.0 to 1.67 and 100% biocompatibility test pass rates by implementing a "Six Sigma + DFMEA" quality management system. In the future, the application of digital twin technology and AI-based process optimization systems will propel medical injection molding toward higher-precision intelligent manufacturing, providing more reliable solutions for global healthcare.

Home

Home