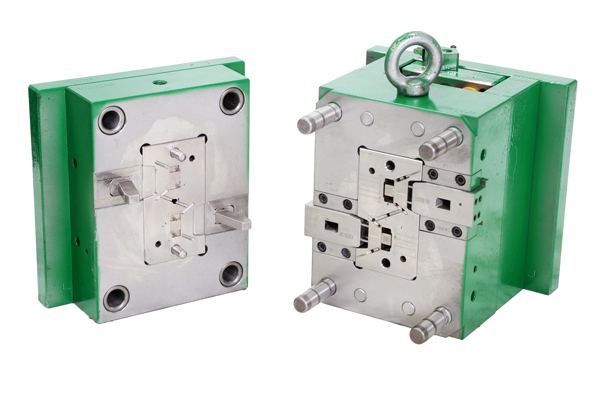

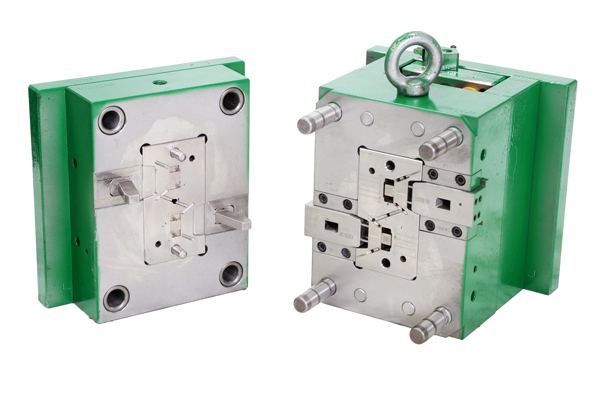

Medical mold manufacturing is a core process in medical device production, directly determining the precision, safety, and reliability of final products. Given the medical industry’s stringent requirements for biocompatibility, sterility, and long-term stability, mold manufacturing demands rigorous control across design, materials, and processes. This article explores three critical considerations: mold design, material selection, and manufacturing processes.

1. Mold Design: Balancing Precision and Functionality

Medical mold design must reconcile product functionality with manufacturing feasibility:

-

Structural Optimization and Precision Control: Medical products (e.g., syringes, catheters, implants) require tight dimensional tolerances. CAD/CAM technologies enable high-precision modeling, with shrinkage compensation reserved to prevent post-molding deformation. For instance, molds for minimally invasive surgical tools must control wall thickness tolerances within ±0.01mm to avoid stress concentration.

-

Ejectability and Cleanability: Simplified ejection mechanisms minimize contamination risks during production. Surface finishes (e.g., polishing or etching) must achieve roughness (Ra) below 0.8μm to prevent residue buildup and ensure sterility.

-

Modularity and Standardization: Modular designs with standardized mold bases and interchangeable cores reduce costs by 50% for small-batch, multi-variety medical products.

2. Material Selection: Balancing Biocompatibility and Durability

Materials must withstand corrosion, wear, and toxicity challenges:

-

Stainless Steel and Specialty Alloys: 316L stainless steel dominates due to its corrosion resistance and polishability, ideal for molds requiring high-temperature sterilization. Tungsten carbide or powder metallurgy high-speed steel (e.g., ASP-23) extends mold life for high-wear applications like orthopedic implants.

-

High-Purity Plastics and Ceramics: PEEK (polyether ether ketone) excels in micro-injection molds for its heat and chemical resistance. Zirconia ceramics suit precision optical medical components due to their low thermal expansion.

-

Surface Treatments: PVD coatings or nitriding enhance corrosion resistance. Diamond-like carbon (DLC) coatings reduce friction and extend mold life by 3–5 times.

3. Manufacturing Processes: Precision and Traceability

Strict process control ensures quality consistency:

-

CNC Machining and EDM: Five-axis CNC milling achieves sub-micron precision for complex cavities, while electrical discharge machining (EDM) shapes microstructures (e.g., microfluidic chips) with minimal thermal damage.

-

Heat Treatment and Stress Relief: Vacuum quenching and cryogenic treatment eliminate internal stresses in tool steels. Deep cryogenic treatment of H13 steel raises hardness by 2–3 HRC and reduces thermal fatigue.

-

Quality Inspection and Traceability: Coordinate measuring machines (CMMs) validate full-dimension accuracy, while non-destructive testing (e.g., X-ray) detects microcracks or porosity.

Home

Home