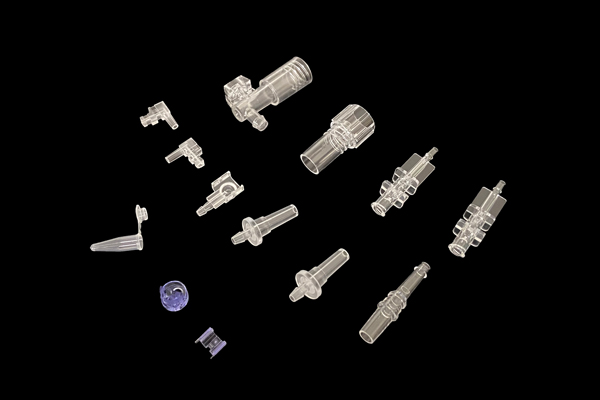

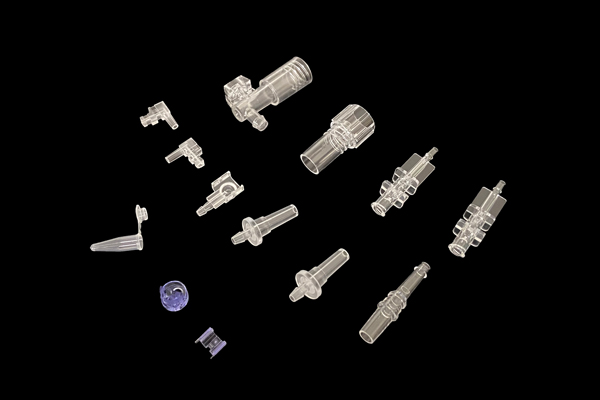

In medical injection molding production, the issue of material shortage is relatively common, seriously affecting product quality and production efficiency. Medical products have extremely high requirements for the precision, performance, and safety of injection-molded parts. Material shortage not only leads to product function failure but may also trigger medical safety hazards. Although material shortage is caused by a combination of factors including raw materials, molds, injection molding processes, and the environment, such as issues with raw material characteristics and quality, mold design and wear, injection molding parameter settings and temperature control, as well as humidity and temperature fluctuations in the workshop environment, we can address it from the following aspects.

Raw Material Aspect

-

Optimize Raw Material Selection: For different medical product requirements, select raw materials with appropriate characteristics. If the product has a complex shape, avoid materials with poor fluidity and high melt viscosity, like polycarbonate (PC) which has low fluidity at low temperatures. Consider replacing them with medical plastics that have better fluidity or adding appropriate flow modifiers to improve fluidity, ensuring the material can fully fill the mold cavity. At the same time, strictly control raw material quality by choosing reputable suppliers to ensure high purity, stable composition, and no mixing of other plastics or additives, as well as uniform particle size distribution to prevent uneven filling or material shortage due to raw material problems.

-

Raw Material Pre-treatment: For hygroscopic medical plastics, conduct sufficient drying before injection molding. Select appropriate drying equipment and process parameters according to the characteristics and requirements of the raw materials, such as drying temperature, time, and airflow velocity, to ensure the moisture content of the raw materials is reduced to the specified range. This prevents the formation of bubbles due to water vaporization during injection molding, which can obstruct melt flow and cause material shortage.

Mold Aspect

-

Improve Mold Design: Design the mold's runner system reasonably. Determine appropriate runner dimensions, lengths, and layouts based on the product's shape, size, and injection volume to reduce the flow resistance of the melt in the runner and ensure sufficient pressure for the melt to reach all parts of the cavity. For molds of complex-shaped medical injection-molded parts, carefully design the sub-runners to ensure uniform flow distribution among the cavities. At the same time, optimize the mold's venting system by setting an adequate number and size of venting slots at appropriate positions on the mold to ensure timely venting of air in the mold cavity and prevent the formation of high-pressure air resistance that affects melt filling.

-

Regular Mold Maintenance: Establish a comprehensive mold maintenance system and regularly inspect, clean, and maintain the mold. Promptly repair wear on the mold cavity surface to restore its dimensional accuracy, ensuring a tight fit between the cavity and the core and preventing melt leakage. Pay special attention to inspecting and maintaining the gate area. If gate wear is found, repair or replace it in a timely manner to ensure the gate dimensions meet the design requirements and maintain stable melt flow rate and pressure as it passes through the gate. Additionally, check the mold's guiding components, such as guide posts and guide sleeves, to ensure wear is within the allowable range, guaranteeing the accuracy and stability of the mold during opening and closing and preventing mold misalignment that can lead to reduced cavity accuracy and sealing, causing material shortage.

Injection Molding Process Aspect

-

Precisely Set Injection Molding Parameters: Based on the characteristics of the raw materials, the mold structure, and the product requirements, determine the optimal injection pressure, injection speed, holding pressure, and holding time through experiments and adjustments. Under the premise of ensuring product quality, appropriately increase the injection pressure to ensure the melt can overcome the resistance in the mold cavity and fully fill it. Reasonably control the injection speed to avoid premature solidification of the melt due to slow speed or turbulence and bubbles due to fast speed. At the same time, ensure sufficient holding pressure and holding time to fully compact the filled melt and eliminate voids inside the product, preventing material shortage.

-

Strictly Control Temperature: Accurately control the barrel temperature and mold temperature. Set an appropriate barrel temperature according to the melting characteristics and processing requirements of the raw materials to ensure the plastic is fully plasticized, with moderate melt viscosity and good fluidity. Avoid excessively high barrel temperatures that can cause plastic decomposition and gas generation, affecting filling performance. Reasonably adjust the mold temperature to meet the cooling and molding requirements of the product. For products with complex shapes and uneven wall thicknesses, different mold temperature control methods can be used, such as local heating or cooling, to ensure uniform cooling and filling of the melt in the cavity.

Environment Aspect

-

Control Workshop Humidity: Install dehumidification equipment, such as dehumidifiers and air conditioners, in the medical injection molding workshop to control the workshop humidity within an appropriate range, generally between 40% and 60%. For hygroscopic raw materials, set up a dedicated drying area in the workshop to further reduce the humidity around the raw materials and prevent them from absorbing moisture from the air. At the same time, strengthen the monitoring and management of workshop humidity and regularly check the operating status of dehumidification equipment to ensure its normal operation.

-

Stabilize Workshop Temperature: Take effective insulation and heat insulation measures to reduce heat exchange between the workshop and the outside environment and maintain stable workshop temperature. Install insulation materials on the walls, roofs, and doors and windows of the workshop to reduce heat conduction and loss. At the same time, reasonably set up the workshop's ventilation system to avoid excessively high or low workshop temperatures due to poor ventilation. For seasons or time periods with large temperature fluctuations, strengthen temperature monitoring and regulation, and adjust the operating parameters of ventilation and heating or cooling equipment in a timely manner to ensure the workshop temperature fluctuates within the specified range and reduce the impact of temperature changes on the injection molding process.

Although the issue of material shortage in medical injection molding is complex, by taking targeted solutions from multiple aspects such as raw materials, molds, injection molding processes, and the environment, we can effectively prevent and control the occurrence of material shortage, improve the quality and production efficiency of medical products, and ensure medical safety.

Home

Home