In the production of medical injection-molded products, air traps represent one of the most common molding defects, directly impacting mechanical performance, biocompatibility, and sterilization reliability. This article systematically analyzes the formation mechanisms of air traps in medical injection-molded products based on principles of material science, fluid mechanics, and mold engineering, providing technical references for the industry.

1. The Essence of Air Traps and Their Medical Implications

Air traps occur when molten plastic fails to expel trapped gases during mold cavity filling, leading to compression and heating of gases. This results in surface defects such as burns, silver streaks, air pockets, or internal voids. In medical applications, air traps pose the following risks:

-

Sterilization failure: Air pockets harbor microorganisms, compromising ethylene oxide (EO) or radiation sterilization efficacy.

-

Drug compatibility risks: Decomposed gases may alter polymer molecular structures, affecting chemical stability with pharmaceuticals.

-

Reduced mechanical strength: Air pockets decrease impact resistance by 30–50%, failing ISO 10993 biocompatibility standards.

2. Five Core Factors Contributing to Air Traps

(1) Material Properties

-

Thermal decomposition: PVC decomposes above 160°C, releasing HCl gas at a rate three times faster than PP. Medical-grade PC has a thermal stability window of only 5 minutes at 320°C, compared to 15 minutes for industrial-grade PC.

-

Moisture absorption: PA66 absorbs 3.5% water; insufficient drying leads to steam expansion (1,200× volume increase) during molding. Medical-grade PPSU requires 4 hours of drying at 150°C to achieve 0.02% moisture content.

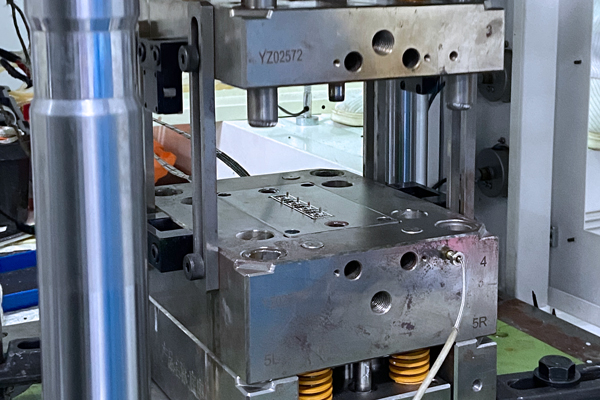

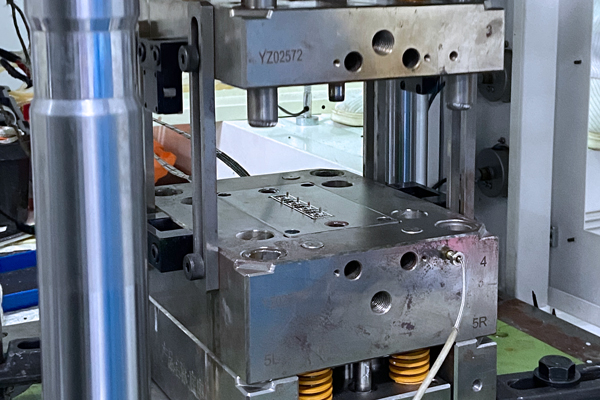

(2) Mold Design Flaws

-

Ineffective venting: Vent slots deeper than 0.03 mm risk molten material leakage, while slots narrower than 0.5 mm (e.g., in insulin pen needle hub molds) increase burn rates by 12%.

-

Unbalanced runner systems: Time differences >0.5 seconds in melt arrival at cavity ends elevate gas compression by 40%. Medical-grade LCP requires runner radii precision of Φ3.2 ± 0.05 mm to avoid vortex-induced air traps.

(3) Process Parameter Errors

-

Injection speed imbalance: Final-stage speeds >80 mm/s raise gas compression temperatures to 450°C, exceeding PP’s heat distortion temperature. Reducing speeds from 100 mm/s to 60 mm/s in blood dialyzer end-cap production cut burn rates from 8% to 0.3%.

-

Packing pressure misuse: Pressures >300 MPa generate 25 MPa cavity gas pressure, causing melt backflow and vacuum voids.

(4) Environmental Control Failures

-

High humidity: Relative humidity >60% creates a 0.1 mm-thick moisture layer on PA66, requiring 8 hours of post-drying degassing.

-

Particle contamination: 0.1 mm metal particles induce localized overheating by 150°C, triggering material decomposition.

(5) Equipment Precision Issues

-

Screw metering instability: Errors >±0.5% in shot size cause 8% cavity fill variation, increasing air trap risk.

-

Hot runner temperature deviations: Medical-grade PEEK requires ±2°C temperature control; deviations create 0.3 mm-scale voids.

3. Air Trap Detection and Prevention Systems

(1) Advanced Detection Technologies

-

Moldflow simulation: Predicts 95% of potential air traps using gas trap analysis modules. Optimizing vent positions reduced trial molds from 7 to 2 in an IVD reagent cartridge case study.

-

Infrared thermography: Surface temperature spikes >15°C during injection indicate air trap formation.

(2) Systemic Solutions

-

Material pretreatment: Dry medical-grade PPSU at 150°C for 6 hours to achieve <0.02% moisture content.

-

Mold venting optimization: Vacuum-assisted venting reduces gas compression by 60% by maintaining -90 kPa initial cavity vacuum.

-

Process parameter control: Implement four-stage injection speed profiles (V1:20→V2:50→V3:80→V4:40 mm/s) and pressure-decay packing (P1:250→P2:200→P3:150 MPa).

-

Equipment maintenance: Maintain screw-barrel clearance at 0.05–0.10 mm and inspect every 5,000 cycles.

4. Case Study: Air Traps in PEEK Hip Joint Implants

-

Problem: 0.5 mm voids in PEEK component ends reduced fatigue life by 40%.

-

Root causes:

-

-

Final-stage injection speeds of 120 mm/s exceeded material thermal limits.

-

Solutions:

-

-

Adjusted speed profile (30→60→90→50 mm/s).

-

Added in-mold vacuum system (-85 kPa initial vacuum).

-

Outcome: Voids eliminated; fatigue life increased from 500,000 to 2,000,000 cycles.

5. Industry Trends

-

Smart venting systems: Adaptive vent valves with pressure sensors adjust gas expulsion in real time.

-

Nanocoatings: 0.1 μm hydrophobic coatings reduce gas adhesion on cavity surfaces.

-

Digital twins: Virtual commissioning cuts trial molds by 70% and accelerates air trap detection by 85%.

Conclusion

Controlling air traps in medical injection-molded products requires a holistic approach integrating material science, mold engineering, and fluid mechanics. By establishing end-to-end control systems—from material pretreatment to equipment maintenance—and leveraging advanced simulation and monitoring technologies, manufacturers can achieve precise defect prevention, meeting the medical industry’s stringent safety and reliability demands.

Home

Home