In the manufacturing process of medical plastic molds, heat treatment is a crucial step to enhance the mold's hardness, wear resistance, and service life. However, deformation during heat treatment has long been a significant challenge plaguing the industry. Deformation not only affects the precision and service life of the mold but may also directly lead to a decline in the quality of medical products. This article will explore effective strategies for preventing deformation issues during the heat treatment process of medical plastic molds from multiple aspects, including design optimization, material selection, and process control.

1. Rational Design of Mold Structure

The structural design of the mold is the primary step in preventing heat treatment deformation. A reasonable mold structure can reduce the generation of thermal and organizational stresses, thereby lowering the risk of deformation.

-

Avoid sharp corners and significant thickness variations: Sharp corners and sections with large thickness differences in mold design are prone to stress concentration during heat treatment, leading to deformation. Smooth transitions, such as rounded or conical transitions, should be used at the junctions of thick and thin sections to reduce thermal stress.

-

Add process holes: For molds where significant thickness variations are unavoidable, process holes can be added to improve cooling uniformity and reduce heat treatment deformation and cracking caused by sectional differences. For example, adding process holes in narrow cavities of die inserts can significantly reduce quenching deformation.

-

Adopt closed and symmetrical structures: Molds with open or asymmetrical shapes are prone to uneven stress distribution after quenching, leading to deformation. Therefore, closed and symmetrical structures should be used whenever possible, or ribs can be left before quenching and then removed afterward to minimize deformation.

-

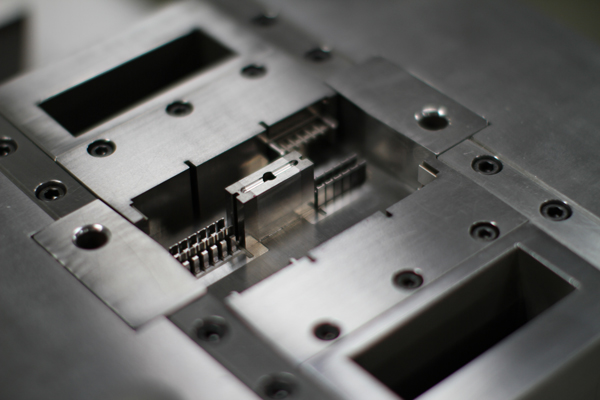

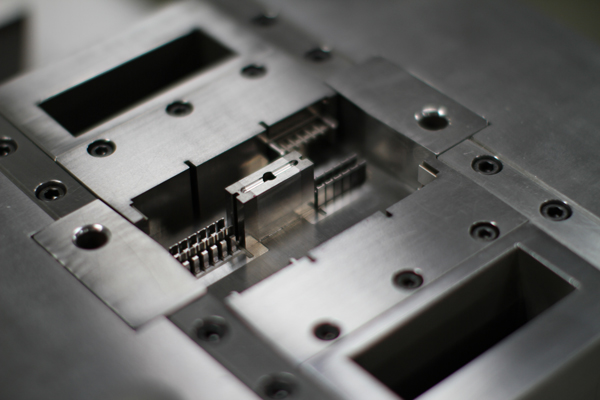

Modular structure: For molds with complex shapes and large sizes, a modular structure can simplify the design, reduce internal surfaces to external surfaces, facilitate hot and cold processing, and effectively reduce deformation and cracking.

2. Scientific Material Selection and Pretreatment

The choice of mold material and the quality of its pretreatment directly affect the degree of deformation during heat treatment.

-

Select high-quality mold steel: Medical plastic molds have extremely high requirements for precision and surface quality. Alloy tool steels with low carbide segregation and good hardenability, such as CrWMn and 9Mn2V, should be preferred. Avoid using low-quality steel from small mills to reduce deformation caused by material defects.

-

Rational forging: Forging is a crucial process for improving carbide distribution and eliminating organizational segregation. High-alloy steel molds require multiple forging passes with a total forging ratio of generally not less than 8-10 to ensure carbide fragmentation and uniform distribution. During forging, the billet should be slowly heated to around 800°C and then to 1100-1150°C, with frequent flipping to ensure uniform heating.

-

Preheat treatment: The forged mold steel should undergo quenching and tempering (quenching + high-temperature tempering) to obtain a uniform and fine tempered sorbite structure, reducing deformation after heat treatment. For high-carbon steel molds, spheroidizing annealing can be used to reduce the volume shrinkage rate during quenching.

3. Optimize Heat Treatment Process

The reasonable control of heat treatment process parameters is the core of preventing mold deformation.

-

Slow heating and graded quenching: Complex molds should be heated slowly below the phase transformation point to reduce internal stresses caused by uneven heating. Graded quenching (e.g., quenching in oil to 170°C and then air cooling) or isothermal quenching processes can significantly reduce thermal and organizational stresses.

-

Control quenching temperature and holding time: Excessive quenching temperatures can lead to coarse grains and increased retained austenite, increasing the risk of deformation. The lower limit of the quenching temperature should be selected as much as possible while ensuring the mold's technical requirements. For example, Cr12MoV steel molds tempered at 500°C have half the retained austenite content compared to those tempered at 200°C, resulting in less deformation.

-

Timely tempering and cryogenic treatment: Quenching should be followed by timely tempering to eliminate thermal and organizational stresses. For precision molds, cryogenic treatment (e.g., low-temperature treatment below -70°C) can further reduce retained austenite and stabilize dimensions.

-

Use protective atmosphere heating: Heating in salt bath or vacuum furnaces can prevent surface oxidation and decarburization of the mold, reducing deformation caused by changes in surface conditions.

4. Strengthen Process Control During Machining

Residual stresses generated during machining are important inducers of heat treatment deformation and need to be reduced through process optimization.

-

Stress relief annealing: Stress relief annealing (e.g., 630-680°C × 3-4h furnace cooling to below 500°C and then air cooling) should be performed after rough machining and before semi-finishing to eliminate machining stresses. For high-precision molds, aging treatment (e.g., 400°C × 2-3h) can be arranged after fine grinding to further stabilize dimensions.

-

Control cutting parameters: Reasonable selection of cutting speed, feed rate, and depth of cut should be made to avoid increased cutting forces and heat accumulation caused by dull tools. For thin-walled parts, increasing the contact area between the workpiece and fixture or using axial clamping can disperse clamping forces and reduce clamping deformation.

-

Reserve machining allowances: Sufficient machining allowances should be reserved before quenching according to the mold's deformation patterns to ensure that the design dimensions can still be achieved through finishing after heat treatment.

5. Implement Full-Process Quality Monitoring

Establishing a full-process quality monitoring system from raw materials to finished products is the fundamental guarantee for preventing deformation.

-

Strictly inspect raw materials: Strengthen the inspection and management of raw materials to prevent mold heat treatment cracking caused by defects such as carbide segregation and banded structures.

-

Record process parameters: Detailed records of process parameters (e.g., heating temperature, holding time, cooling medium) for each process should be kept to provide data support for deformation analysis.

-

Regularly maintain equipment: Ensure the temperature uniformity and control accuracy of heat treatment equipment (e.g., quenching furnaces, tempering furnaces) to avoid process fluctuations caused by equipment failures.

Home

Home