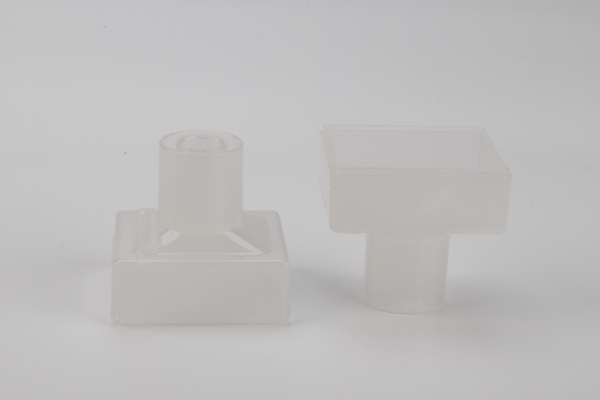

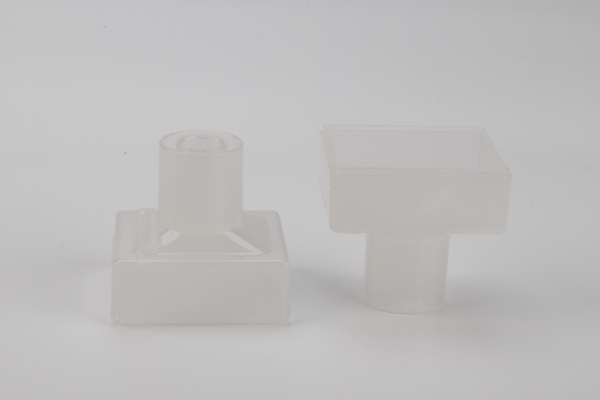

In the field of medical injection molding, gas mark defects have emerged as a critical challenge affecting product yield and compliance. A medical device company once faced a recall of over RMB 10 million due to gas marks on the surface of infusion set connectors, while a high-value consumable injection-molded part led to order losses following customer complaints about gas marks. These cases underscore the unique importance of gas mark control in medical products—it not only impacts appearance quality but also relates to core performance indicators such as sealing and biocompatibility. This article systematically explores the mechanisms of gas mark formation from three dimensions—material properties, mold design, and process parameters—and provides actionable solutions.

I. The Uniqueness of Medical-Grade Materials: The "Invisible Driver" of Gas Marks

Medical injection molding commonly uses materials such as PPSU, PEEK, and LCP, which generally feature high melting points and high viscosity. For example, a specific brand of PPSU has a melt flow rate of only 8-12 g/10 min (280°C/5 kg), significantly lower than the 20-25 g/10 min of ordinary PC. These characteristics lead to:

-

Intensified Shear Heating: Under screw shear, material temperatures can spike by 30-50°C instantaneously, triggering localized thermal decomposition. Experimental data from one company shows that when screw speed increases from 60 rpm to 120 rpm, the amount of gas generated by PPSU decomposition rises by 2.3 times.

-

Abrupt Gas Solubility Changes: Medical materials can dissolve 10-15 times more gas in their molten state than in their solid state. When molten material transitions from the barrel to the mold cavity, pressure drops cause rapid gas precipitation, forming microbubble clusters.

-

Additive Effects: To meet biocompatibility requirements, medical materials often incorporate glass fibers, antibacterial agents, etc. Research indicates that adding 20% glass fiber to PEEK increases exhaust requirements by 40% compared to pure material.

Solutions:

-

Implement "dual-temperature control": Keep the rear barrel temperature 10-15°C lower than the front section to reduce material pre-decomposition.

-

Utilize vacuum drying systems: Maintain material moisture content below 0.02% (compared to 0.05% for ordinary injection molding).

-

Optimize screw design: Use barrier-type screws with a compression ratio of 2.5:1-3:1.

II. Mold Design's "Gas Sealing Traps": 90% of Gas Marks Originate from Exhaust Failure

The precision requirements of medical molds far exceed those of ordinary molds, creating exhaust challenges:

-

Microstructure Exhaust Dilemmas: The runner diameter of a cardiac stent mold is only 0.8 mm, requiring exhaust slot depths of 0.01-0.015 mm (compared to 0.03-0.05 mm for ordinary molds). Minor deviations can cause blockages.

-

Multi-Cavity Mold Balancing Issues: In a 16-cavity infusion set connector mold, pressure loss differences in the runner system can reach 15%, causing some cavities to fill too quickly and trap gas.

-

Hot Runner Dead Zones: One company's statistics show that residual gas in hot runner systems accounts for 32% of gas mark defects. Particularly, 0.05 mm gaps in needle-valve hot nozzles can retain 0.003 cm³ of gas.

Innovative Design Cases:

-

A "gradient exhaust system" developed by one company: Features 0.01 mm main exhaust slots on the parting surface combined with ejector pin gap exhaust (Ø0.15 mm × 4 groups), reducing gas mark rates in a catheter connector from 18% to 0.5%.

-

Adoption of porous steel inserts: Embedding PM-35 porous steel in gas trapping areas provides a permeability coefficient of 8×10⁻¹² m², enabling mark-free exhaust.

-

Moldflow optimization: By adjusting exhaust slot positions to melt front convergence points through simulation, one artificial joint mold saw gas mark incidence drop by 76%.

III. The "Golden Triangle" of Process Parameters: Dynamic Balance of Speed-Pressure-temperature

Medical injection molding exhibits 3-5 times greater sensitivity to process parameters than ordinary products, requiring a "three-level control system":

-

Multi-Stage Injection Speed Control:

-

First stage (0-20% filling): Use 20-40 mm/s low speed to avoid vortex formation at the gate.

-

Second stage (20-80% filling): Increase to 80-120 mm/s high speed to shorten filling time.

-

Third stage (80-100% filling): Reduce to 30-50 mm/s to prevent end-of-fill gas trapping.

-

Packing Pressure Curve Design:

-

One company developed a "dual-peak packing" process: Apply 85% injection pressure at the first peak (end of filling) and 65% at the second peak (30% cooling), effectively reducing sink mark-gas mark overlap defects.

-

Precise Mold Temperature Control:

-

Employ oil temperature controllers + water temperature controllers for ±0.5°C mold temperature fluctuations.

-

Implement "stepped heating" for PPSU: 85°C front mold, 90°C rear mold, and 95°C core to promote gas migration toward the parting surface.

Real-Time Monitoring Technologies:

-

Install melt pressure sensors: Place monitors at the nozzle and runner end to trigger alarms when pressure differentials exceed 5 MPa.

-

Use infrared thermal imagers: Scan mold surface temperature distributions every 2 hours to detect localized overheating.

-

Develop AI process optimization systems: Generate optimal parameter combinations through machine learning analysis of 100,000 process data sets.

IV. Special Requirements for Medical Injection Molding: From Clean Production to Validation Systems

-

Cleanroom Environment Control:

-

Maintain ISO Class 7 (10,000) cleanliness with suspended particles ≤3.52 million/m³ (0.5 μm).

-

Implement ESD protection systems: Control mold surface resistance between 10⁶-10⁹ Ω to prevent electrostatic dust adhesion.

-

Material Traceability Systems:

-

Establish "five-code integration" management: Track raw material batch codes, mold numbers, machine IDs, operator IDs, and production dates.

-

Create gas mark defect databases: Record defect locations, sizes, and morphologies for each mold to guide process improvements.

-

Verification & Validation (V&V):

-

Complete DQ (Design Qualification), IQ (Installation Qualification), OQ (Operational Qualification), and PQ (Performance Qualification) per ISO 13485 requirements.

-

Implement "three-batch full inspection": Conduct 100% gas mark detection on first, middle, and final production batches using fiber-optic sensors for 0.01 mm defect resolution.

Conclusion: Future Trends in Gas Mark Control

As medical injection molding advances toward "micro-nano" (feature sizes <0.1 mm) and "multi-material" (e.g., PEEK + titanium alloy composites) applications, gas mark control faces greater challenges. Emerging technologies such as intelligent exhaust systems, nanoscale mold polishing, and supercritical fluid-assisted injection molding are gaining traction. One company has successfully developed "self-exhausting molds" that use micro-nano structures on core surfaces to enable autonomous gas migration, reducing gas mark rates in implants to below 0.03%. This indicates that the future of medical injection molding will enter a "zero gas mark" era, requiring deep integration and innovation across material science, mold technology, and process control.

Home

Home