In the era of rapid technological advancement and the booming medical industry, medical consumables play an indispensable role in clinical diagnosis, treatment, and nursing processes, with their market demand showing a continuous growth trend. However, for numerous medical device enterprises, start - up companies, and research institutions, independently completing the entire process of medical consumables from R&D design, production manufacturing, to quality control faces multiple severe challenges in terms of capital, technology, equipment, and manpower. Against this backdrop, professional medical consumables contract manufacturers have emerged as a key force in driving the efficient development of the medical industry.

I. Insight into the Market: The Urgent Demand and Industry Pain Points of Medical Consumables Contract Manufacturing

With the deepening of population aging, the rapid progress of medical technology, and the occasional occurrence of public health events, the market scale of medical consumables is expanding at an unprecedented speed. However, enterprises often encounter numerous difficulties in the process of self - producing medical consumables.

On the one hand, the production of medical consumables has extremely high requirements for the production environment, professional equipment, and advanced technology. Building a complete production line requires a huge initial investment in the construction of clean workshops, the purchase of professional equipment, and the introduction of advanced technology. For small - and medium - sized enterprises, this is undoubtedly a heavy burden and may even become a stumbling block to their development.

On the other hand, the R&D and production of medical consumables involve multiple disciplines such as medicine, materials science, and engineering. The shortage and difficulty in cultivating professional talents make it difficult for enterprises to respond quickly to market demands and launch new products that meet market needs. In addition, strict regulations and quality standards, such as the Good Manufacturing Practice for Medical Devices (GMP) and the ISO 13485 Quality Management System, also impose enormous compliance pressures on enterprises during the production process. A slight misstep may lead to serious legal consequences.

II. Showcasing Strength: The Core Advantages of Professional Medical Consumables Contract Manufacturers

(1) Advanced Equipment and Technology, Forging Excellent Quality

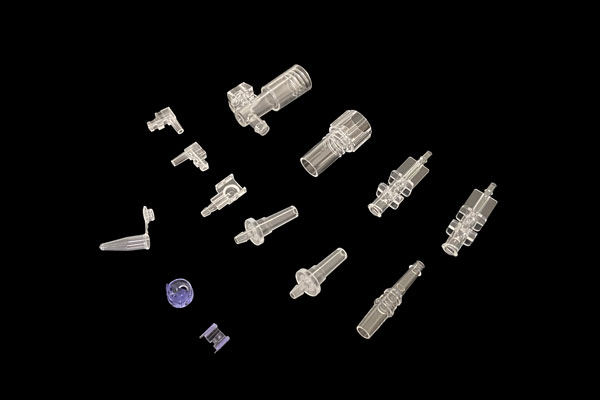

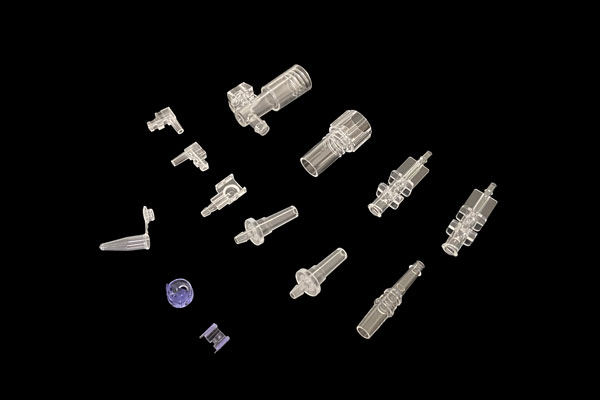

As a professional medical consumables contract manufacturer, Yize Mould is equipped with advanced production equipment covering the entire process. There are not only high - precision injection molding machines, automated assembly lines, but also ISO7 - level and above clean workshops (Class 10,000 clean rooms), providing a clean and efficient environment for the production of medical consumables. In addition, we have special equipment such as blister packaging, ultrasonic welding, and plastic tube bending machines, which can complete the production of medical consumables from molding to packaging in a one - stop manner. At the technical level, we deeply integrate processes such as micro - injection molding, ultrasonic welding, and sterilization treatment with medical precision mold development and medical precision injection molding technology to ensure that products meet the standards of high precision, high stability, and high safety.

(2) Full - Cycle Development, Empowering Product Innovation

Our professional team has the ability to provide full - chain services from design to implementation. In the product design stage, through Design for Manufacturability (DFM), we can identify design defects in advance to avoid rework in the later stages, saving time and costs for customers. At the same time, we use product design optimization technology to reduce production costs while meeting functional requirements. For example, in the development of micro - infusion pump consumables, the original design of the infusion tube interface structure by the customer was complex, leading to high mold development difficulty and low injection molding yield. Our team simplified the interface structure through DFM and optimized the runner design. As a result, the mold development cycle was shortened by 30%, and through medical precision injection molding technology, the inner diameter tolerance of the tube was controlled within ±0.02mm, ensuring the infusion accuracy and greatly improving production efficiency and product quality.

(3) Stringent Control, Ensuring Quality Assurance

From raw material procurement inspection, production process monitoring, to finished product full - performance testing, we have established a comprehensive quality control system covering medical mold manufacturing, medical precision injection molding, blister bag packaging, sterilization treatment, and other post - processes. Every link has strict standards and procedures to ensure that product quality meets the highest industry standards.

(4) Flexible Customization, Meeting Diverse Needs

We provide flexible and diversified customization services. Whether it is a small - batch trial production or a demand for tens of thousands of units, we can meet it by quickly switching production modes. For special medical consumables, we can provide personalized assembly solutions, such as customized bending and assembly services for dental consumables, truly achieving "tailor - made" services from product development to delivery and meeting the diverse needs of customers.

III. Efficient Collaboration: The Cooperation Process of Medical Consumables Contract Manufacturing

(1) Demand Communication and Precise Evaluation

After customers put forward their demands, our technical team will conduct a comprehensive evaluation of the product's functions, performance, specifications, etc., based on professional product design for manufacturability analysis capabilities. At the same time, we will provide customers with an overall plan and cost budget covering medical precision mold development, injection molding technology, packaging and sterilization, etc., so that customers have a clear understanding and expectation of the project.

(2) R&D Design and Precise Prototyping

We use advanced tools such as Computer - Aided Design (CAD) and Mold Flow finite element analysis to complete product design optimization and rely on medical precision mold manufacturing technology to complete sample production. At this stage, we simultaneously develop supporting solutions such as blister packaging design and sterilization process planning to ensure seamless integration between the product and packaging and sterilization processes, laying a solid foundation for the smooth launch of the product.

(3) Mass Production and Strict Inspection

After entering mass production, we achieve efficient and stable production through automated production lines and process equipment such as ultrasonic welding and tube bending. Each batch of products must pass multiple inspection procedures such as packaging sealability testing and sterilization effect verification to ensure that the delivery quality meets customer requirements.

(4) Thoughtful Services and Continuous Support

We provide comprehensive after - sales support, including free pre - sales technical support and quality traceability services. In response to customers' iterative demands, we can quickly initiate secondary development such as mold optimization and process adjustment to continuously empower product upgrades and establish long - term and stable cooperative relationships with customers.

IV. Win - Win Cooperation: The Far - Reaching Significance of Choosing Professional Medical Consumables Contract Manufacturers

For enterprises and institutions, choosing Yize Mould as a contract manufacturing partner can enable them to focus more on their core businesses. Through our one - stop services, we can help reduce the full - process cost and shorten the time - to - market cycle. We not only provide high - end manufacturing capabilities such as medical precision molds and injection molding but also incorporate processes such as blister packaging and sterilization treatment into our service system to ensure full - chain quality control of products from R&D to end - use. With years of industry experience and technological accumulation, we have helped numerous enterprises achieve product innovation and capacity breakthroughs. In the future, we will continue to deeply cultivate the field of medical consumables contract manufacturing and work hand in hand with customers to promote the high - quality development of the medical industry.

If you have medical consumables contract manufacturing needs, please feel free to contact us. Let us safeguard your medical products with our professional technology and comprehensive services and jointly open up a bright future for the medical industry!

Home

Home