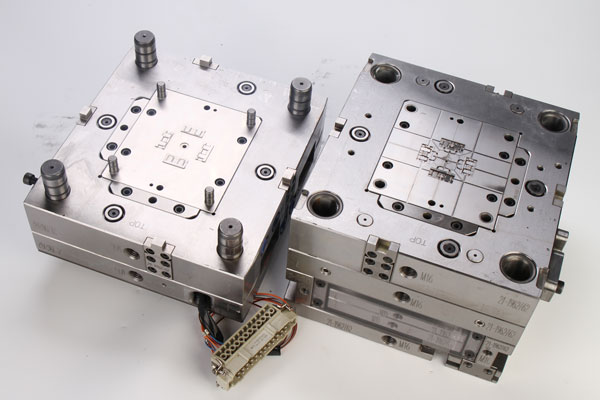

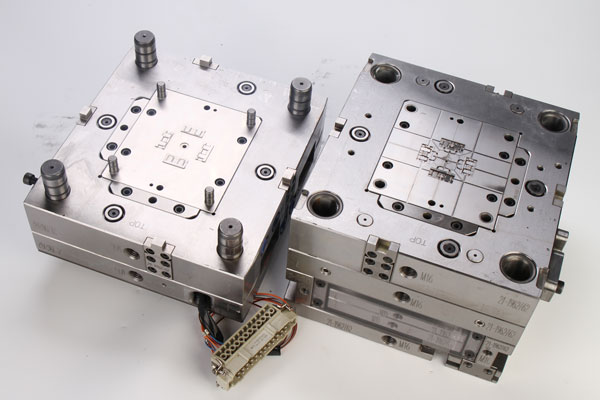

In the booming medical industry, the quality of medical products is directly related to patients' lives and health. Medical precision molds, as a key element in ensuring the quality of medical products, are involved in the entire manufacturing process of reagent boxes, reagent strips, minimally invasive medical components, and various precision medical device components. The precision and safety of these medical products all depend on the support of high - quality molds. However, at present, many enterprises in the field of medical precision mold development often fall into the predicament of "post - remedy" due to insufficient attention paid to key links such as product structure design, steel material selection, and processing technology in the early stage. This not only significantly increases costs but may also have a serious impact on product quality and production schedule.

I. Ignoring Key Links, Frequent Pain Points Occur

(1) Improper Selection of Steel Materials, Hiding Quality Risks

Steel materials can be regarded as the "skeleton" of molds, and their selection plays a decisive role in the performance and service life of molds. Some enterprises, in order to reduce short - term costs, choose pre - hardened steel materials for precision mold manufacturing, ignoring their high susceptibility to wear during the production process. Pre - hardened steel materials have insufficient strength, and long - term use can lead to collapse and deformation of the parting surface, seriously affecting mold precision and further causing a series of quality problems such as dimensional deviations and appearance defects in medical products. Taking transparent plastic products as an example, such as PC, PMMA, and PS, if S136 fully hardened stainless steel is not selected but inappropriate steel materials are used, the polishing effect of the mold will be greatly compromised, the surface roughness will increase, seriously affecting the product transparency. Moreover, it will be extremely difficult to maintain the mold later, and even re - tooling may be required, which will consume a large amount of time and cost.

(2) Rough Processing Technology, Difficult to Guarantee Precision

Processing technology is the core link in achieving mold precision. Fast - wire electrical discharge machining (EDM), ordinary spark machines, and low - precision CNC machines are prone to causing dimensional deviations in molds during the processing process due to their limited precision. Some enterprises, in order to save processing costs, adopt rough processing technologies. When dimensional problems occur, they try to remedy them through manual "fitting", but this method is not only inefficient but also fundamentally unable to meet the requirements of precision molds, ultimately leading to mold scrap.

(3) Unreasonable Product Structure Design, Increasing Mold Difficulty

In the early stage of product research and development, insufficient understanding of the needs of medical products can lead to unreasonable product structure design, which in turn imposes excessively high precision requirements on molds. For example, some medical product designs have complex structures and narrow spaces, which require molds to have extremely high precision, undoubtedly increasing the difficulty and cost of mold development. At the same time, over - pursuing high precision while ignoring actual usage requirements can lead to excessive quality control during the production process, resulting in a waste of resources.

II. Full - Process Management and Control to Create High - Quality Molds

(1) Accurate Selection of Steel Materials, Laying a Solid Foundation for Molds

Selecting appropriate steel materials according to product structure and plastic characteristics is the first step in mold development. For medical precision molds, giving priority to fully hardened steel materials is a wise choice. Although rough and precision machining need to be carried out separately, the processing cost is similar to that of pre - hardened steel materials, but it can effectively avoid problems such as wear and deformation caused by pre - hardened steel materials. For transparent plastic products such as PC, PMMA, and PS, it is necessary to insist on using S136 fully hardened stainless steel to ensure that the steel material has good polishing performance, improve product transparency, and facilitate later mold maintenance, thereby extending the service life of the mold.

(2) Optimal Selection of Processing Technology, Ensuring Mold Precision

Choosing high - precision processing equipment is crucial during the processing process. Slow - wire EDM has higher precision compared to fast - wire EDM and can meet the dimensional requirements of precision molds. High - precision spark machines and CNC machines can ensure the surface roughness and dimensional precision of molds. By adopting advanced processing equipment and technologies, dimensional deviation problems can be avoided from the source, reducing the need for later manual corrections and improving mold production efficiency and quality.

(3) Optimizing Product Structure, Reducing Mold Costs

In the early stage of product research and development, it is necessary to have a deep understanding of the needs of medical products and work closely with the design team to optimize the product structure. Through reasonable structure design, excessively high precision requirements for molds can be avoided, and the difficulty and cost of mold development can be reduced while meeting product functions and quality requirements. For example, simplifying complex structures and reasonably designing demolding angles can not only ensure the smooth production of products but also reduce the workload and cost of mold processing.

(4) Strengthening Project Management, Controlling Full - Process Quality

Excellent project management is the key to the success of medical precision mold development. Establish a project team with a full - process knowledge system to strictly control each link from product structure design, steel material selection, processing technology to production quality control. The project team should deeply understand customer needs, coordinate cooperation among various departments, and promptly solve problems that arise during the development process to ensure that mold development proceeds smoothly according to the plan and that mold quality meets the requirements.

III. Summary

The development of medical precision molds is a full - process systematic project that covers product structure design, steel material selection, analysis of plastic properties, selection of processing methods, and production quality control. Neglecting any link may lead to irreparable mistakes later, increasing costs and affecting product quality. Yize Mould has deeply realized the importance of full - process management and control in decades of medical precision mold development. We have a professional project management team that can deeply understand customer needs and optimize product structure design; strictly control steel material selection, cooperate with high - quality suppliers to ensure steel material quality; and are equipped with advanced processing equipment and adopt high - precision processing technologies to guarantee mold precision. We always put customer needs first, reasonably control costs while ensuring quality, and are committed to providing customers with high - quality medical precision mold solutions and contributing to the development of the medical industry.

Home

Home