Want to understand the production cycle of medical injection molds? First, we need to delve into the internal production process of medical injection mold factories. Below is a detailed analysis of the production cycle for medical injection molds.

In the medical field, the manufacturing requirements for injection molds are more stringent because the products directly relate to patients' health and safety. Therefore, from the moment clients provide quotation drawings for medical injection molds, the entire production process needs to be more meticulous and rigorous.

1. Quotation and Preliminary Design Phase

During the quotation and preliminary design phase of medical injection molds, in-depth communication with clients is necessary to ensure that the mold design meets the special requirements of medical products. This phase typically requires 15-20 days to complete the preliminary structural design drawings. During this period, clients also need some time to select a mold factory. We will submit the preliminarily completed structural drawings to clients for supplier negotiation, allowing us to further optimize, review, and modify the product while clients negotiate with suppliers. By the time clients select a supplier, our structural design is almost complete, aligning perfectly with the mold supplier's review phase.

2. Design Review and Optimization

Transforming a design plan into an actual product requires multiple rounds of review and optimization. The design of medical injection molds is particularly crucial as it directly affects the quality and safety of the products. Each structural engineer's design needs to be carefully reviewed by other engineers. Different perspectives and angles of observation lead to varied judgments. The initial review usually takes about half a day to one day, with another structural engineer conducting a comprehensive check of the drawings, including appearance, scheme assessment, component compatibility, surface processes, mold feasibility, and production assembly sequence. Subsequently, a collective review meeting is held, involving all structural department members and relevant ID designers, to discuss and list the issues identified during the initial review, ensuring that the issued drawings represent the company's highest standards.

3. Structural Hand Model Production and Review

After the structural design is completed, a structural hand model needs to be produced for physical verification. The production of the structural hand model takes about four days, with its appearance and dimensions required to be consistent with the drawings to closely resemble the final injection-molded product. During the hand model production period, we can send the ID process annotations, BOM, and 3D drawing data to clients, scheme companies, and the selected mold factory for review. This review process generally takes 1-2 days, with clients, scheme companies, and the mold factory providing their opinions and suggestions. The design company updates and optimizes the drawings based on the feedback.

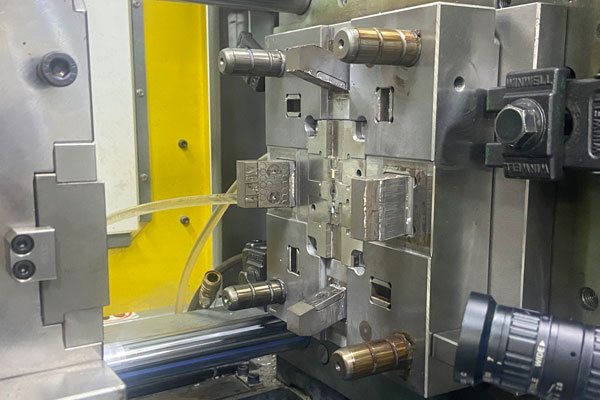

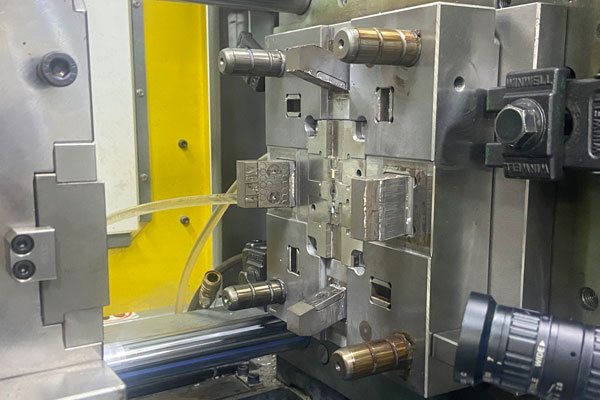

4. Mold Manufacturing and Trial Molding Phase

After multiple rounds of review and optimization, the mold opening phase begins. The mold manufacturing time for medical injection molds is relatively long, usually taking 18-25 days, depending on the complexity and precision requirements of the mold. During the mold opening period, the design company needs to follow up on the project's progress to ensure that all necessary components are prepared. After mold opening, trial molding and mold modification work are carried out. During trial molding, the structural design engineer accompanies the client to the mold factory to conduct single-item and assembly inspections of all components, identifying and rectifying issues to meet design requirements.

5. Mass Production Preparation and Delivery

After multiple trial moldings, mold modifications, and inspections, if the samples are confirmed to be error-free, mass production can be arranged. Before mass production, all issues need to be properly resolved to ensure the smooth progress of the mass production process. The mass production process for medical injection molds typically does not require the direct involvement of structural design engineers, but the design company provides necessary technical support and after-sales service.

In summary, the production cycle of medical injection molds is relatively long, spanning from quotation and preliminary design to mass production preparation and delivery. The entire process may take several months, depending on the mold's complexity, precision requirements, and the communication efficiency between clients and suppliers. If you wish to inquire about the specific production cycle or obtain a free quotation, please feel free to contact us. We are a company dedicated to the manufacturing of medical injection molds, with rich experience and advanced production equipment, committed to providing high-quality mold products and excellent services to our clients.

Home

Home