In the medical field, polypropylene (PP) has emerged as a cornerstone material in injection molding due to its lightweight properties, chemical resistance, and biocompatibility. From disposable syringes to advanced diagnostic equipment, PP materials continue to push the boundaries of application through precision injection molding technology, bringing revolutionary changes to the medical industry.

This article delves into the core advantages of PP in medical injection molding, its typical applications, and future development directions, combining industry practices and technological breakthroughs.

1. Core Advantages of PP in Medical Injection Molding

-

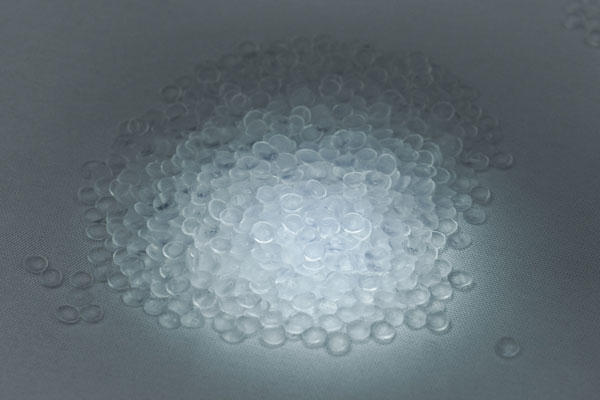

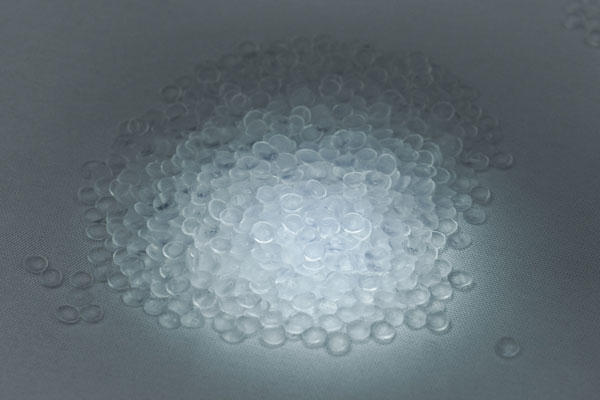

Biocompatibility and Chemical Stability: PP is non-toxic, odorless, and BPA-free, complying with ISO 10993 biocompatibility standards. It can directly contact human tissues or drugs. For example, Zhongyuan Petrochemical's medical-grade transparent PP material PPR-MT20, certified under YY/T 0242-2007, is widely used in precision components such as syringe needles. Its resistance to weak acids, weak bases, and organic solvents ensures stability during sterilization.

-

Processability and Cost Control: With a melting point of 220-270°C, PP can be molded through various processes such as injection, extrusion, and blow molding. Its low water absorption (<0.01%) reduces the need for drying, lowering production costs. For instance, North Huajin Chemical's RP344P-K material achieves a balance between high transparency and high fluidity through optimized molecular chain structure, shortening the injection cycle to less than 15 seconds and significantly improving production efficiency.

-

Material Classification and Functional Adaptability: PP can be categorized into homopolymer PP (PP-H), impact-resistant PP (PP-B), and transparent PP (PP-R) based on molecular structure:

-

PP-H: High rigidity and temperature resistance, suitable for structural components such as nebulizer cups and centrifuge tubes.

-

PP-B: Enhanced impact resistance through ethylene block copolymerization, commonly used in medical connectors and catheter clips.

-

PP-R: Random copolymerization grants it high transparency, widely used in visualization components such as infusion bags and blood collection tubes.

2. Typical Applications in Medical Injection Molding

-

Disposable Medical Devices: PP dominates in disposable syringes, infusion sets, etc. For example, Sinopec SABIC's gamma-irradiation-resistant PP material GA260R maintains dimensional stability after γ-ray sterilization, solving the brittleness issue of traditional materials. Its surface smoothness reaches Ra≤0.8μm, effectively reducing drug residue risks.

-

Components for High-End Diagnostic Equipment: In CT scanners, ultrasound diagnostic devices, etc., PP is used to manufacture enclosures, connectors, and internal brackets. For instance, Borealis' Bormed BJ868MO material achieves injection molding precision of ±0.02mm through heterophasic copolymerization, meeting the stringent requirements for micro-components in medical equipment. Its antistatic properties (surface resistance 10⁹-10¹¹Ω) prevent dust adhesion, ensuring long-term reliability.

-

Wearable Medical Devices: With the rise of smart bracelets and continuous glucose monitors, PP's lightweight properties (density 0.9g/cm³) make it a preferred choice for enclosures. For example, a glucose meter uses PP-R material for its enclosure, with a thickness of only 1.2mm and a 30% weight reduction, while achieving high-precision labeling through laser engraving.

3. Technical Challenges and Breakthrough Directions

-

Improvement of High-Temperature Resistance: Traditional PP materials have insufficient heat resistance (long-term use temperature <100°C), limiting their application in high-temperature sterilization scenarios. Germany's Centroplast has introduced Centrolab HTTM/PP-HT material, which enhances the heat deflection temperature to 140°C through the addition of nano-scale inorganic fillers, enabling it to withstand 132°C steam sterilization and suitable for high-temperature components such as surgical instrument trays.

-

Surface Modification Technology: PP's surface inertness makes it difficult to print or bond directly. To address this, the industry has developed surface modification technologies such as plasma treatment and chemical etching. For example, a company reduced the surface wetting angle of PP from 108° to 35° through low-temperature plasma treatment, significantly improving ink adhesion and meeting the labeling requirements of medical devices.

-

Development of Bio-Based PP: With the growing demand for sustainability, bio-based PP has become a research hotspot. Netherlands-based Lyondellbasell has launched Purell RP320M material, produced from sugarcane, reducing the carbon footprint by 40% while maintaining medical-grade performance. Its injection-molded parts have passed FDA food contact certification and are suitable for drug packaging applications.

4. Future Trends and Industry Outlook

-

Application of Composite Materials: By combining PP with glass fibers, carbon fibers, etc., the material's strength can be significantly enhanced. For example, a company's PP/GF30 material achieves a tensile strength of 120MPa and a flexural modulus of 5GPa, suitable for high-strength applications such as orthopedic devices.

-

Intelligent Injection Molding Processes: Integrating IoT and AI technologies enables real-time monitoring of parameters such as temperature and pressure, optimizing the process curve. For example, a company introduced an AI vision inspection system to detect defects in PP injection-molded parts, improving the yield rate to 99.8% and increasing production efficiency by 25%.

-

Driving Personalized Medicine: The combination of 3D printing technology and PP materials provides possibilities for personalized medical devices. For example, a research team used selective laser sintering (SLS) technology with PP powder to print patient-customized orthoses, improving fit by 50% and shortening the treatment cycle by 30%.

Conclusion

The application of PP materials in medical injection molding represents not only a breakthrough in materials science but also a crucial support for the medical industry's advancement toward precision and intelligence. From disposable consumables to high-end equipment, from traditional processes to intelligent manufacturing, PP materials are reshaping the medical ecosystem with an innovative stance. In the future, with the further development of bio-based materials, composite materials, and intelligent processes, PP will unleash greater potential in the medical field, contributing more value to human health.

Home

Home