With the vigorous development of the global medical and healthcare industry, the medical injection molding industry, as a crucial link in medical device manufacturing, is ushering in unprecedented development opportunities. From disposable medical supplies to high-end implants, and from diagnostic equipment to surgical instruments, injection molding technology, with its advantages of high precision, low cost, and capacity for mass production, has become an important force driving the innovation and popularization of medical devices.

According to the latest market research reports, the global market size for medical injection molding continues to grow steadily and is expected to reach USD 1.417 billion by 2031, with a compound annual growth rate of approximately 2.4%. This growth is mainly attributed to factors such as an aging population, a rising incidence of chronic diseases, and an explosion in medical demand in emerging markets. Among them, the North American and European markets hold a dominant position, but the Asian market, especially the Chinese market, is rising at an astonishing speed. China's medical device injection molding industry has entered a mature stage of development, with the number and scale of enterprises reaching record highs, forming a group of leading enterprises with international competitiveness.

In China, with the increased policy support and optimized investment and financing environment, the medical injection molding industry has entered a period of rapid development. Breakthroughs made by domestic medical devices in high-end fields, such as "brain pacemakers", 5.0T magnetic resonance imaging systems, and third-generation artificial hearts, have not only enriched market supply but also promoted the continuous upgrading of injection molding technology. Meanwhile, domestic enterprises have gradually narrowed the gap with international giants by introducing advanced international technologies and increasing R&D investment.

Technological Trends: Automation, Intelligence, and Miniaturization Lead Industry Transformation

Automation and Intelligence

With the advent of the Industry 4.0 era, the medical injection molding industry is accelerating its transformation towards automation and intelligence. Automated injection molding machines achieve precise control over materials and finished products by integrating sensors, metering devices, and advanced control systems, significantly shortening production cycles and improving product quality. The application of intelligent equipment, such as robotic arms and visual inspection systems, further enhances production efficiency and flexibility, reducing labor costs. For example, Battenfeld's Microsystem50 precision injection molding machine in Germany realizes high-precision production of micro plastic parts through a three-stage precision metering extrusion-injection composite system.

Miniaturization

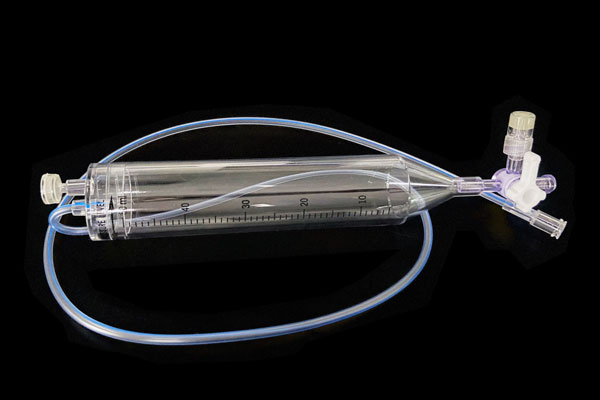

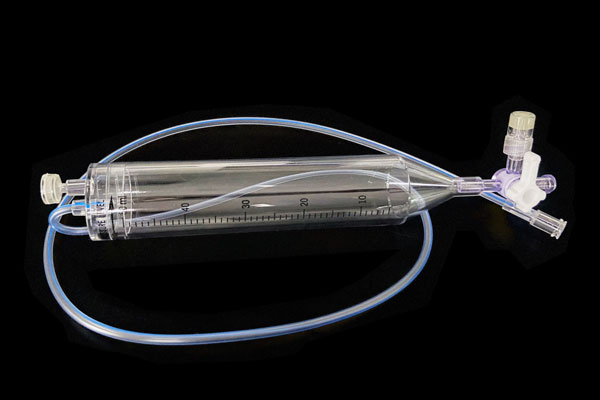

Miniaturization is another major trend in the medical injection molding industry. With the advancement of medical technology, more and more medical devices are moving towards smaller size and higher precision. Micro injection molding technology can produce micro parts with overall dimensions, functional features, or tolerance requirements measured in millimeters or even micrometers, such as pipettes and insulin dosing pens. These micro devices not only have a smaller size and lower cost but also possess better biocompatibility and functionality, meeting the needs of modern medicine for precise treatment.

New Materials and New Processes

The application of new materials is also an important factor driving the development of the medical injection molding industry. For example, PEEK material is widely used in the manufacture of implantable medical devices due to its strong corrosion resistance, hydrolysis resistance, and chemical resistance. At the same time, the introduction of new processes such as multi-component injection molding and in-mold assembly further improves product quality and precision and reduces production costs.

Challenges and Opportunities: Coexistence of Technological Barriers and Market Demand

Despite the broad prospects of the medical injection molding industry, it also faces numerous challenges. Firstly, there are high technological barriers, requiring precise molds and injection molding equipment, as well as professional technical personnel. This, to a certain extent, restricts market development, especially making it difficult for small and medium-sized enterprises to enter the high-end market. Secondly, the medical device industry is subject to strict regulations and needs to meet various standards and regulatory requirements, which increases the operating costs and time costs of enterprises. In addition, rising raw material prices and labor costs also bring cost control pressure to enterprises.

However, challenges and opportunities coexist. With the continuous growth of global medical demand, the medical injection molding industry will迎来 more development opportunities. Especially in emerging markets, such as Asia and Africa, with economic growth and improved medical standards, the demand for medical devices will continue to increase. At the same time, the demand for high-end medical devices is also growing steadily, providing more opportunities for the injection molding market.

Future Outlook: Parallel Development of Technological Innovation and Industrial Upgrading

Looking ahead, the medical injection molding industry needs to continue to increase its efforts in technological innovation and promote industrial upgrading. On the one hand, enterprises need to continuously introduce and develop advanced injection molding equipment and technologies to improve production efficiency and product quality. On the other hand, they need to strengthen cooperation with scientific research institutions and universities to jointly overcome technological difficulties and promote the application of new materials and new processes.

At the same time, enterprises also need to focus on brand building and market expansion. By enhancing brand image and service quality, they can strengthen market competitiveness. By expanding domestic and foreign markets, they can achieve large-scale development. In addition, with the enhancement of environmental awareness, green manufacturing will also become an important development direction for the medical injection molding industry. Enterprises need to actively adopt environmentally friendly materials and production processes, reduce energy consumption and emissions, and achieve sustainable development.

The medical injection molding industry, as a crucial link in medical device manufacturing, is ushering in unprecedented development opportunities. Driven by the dual forces of technological innovation and market demand, the industry will continue to move towards a higher level of development. For enterprises, only by seizing opportunities, meeting challenges, and continuously innovating and upgrading can they remain invincible in the fierce market competition.

Home

Home