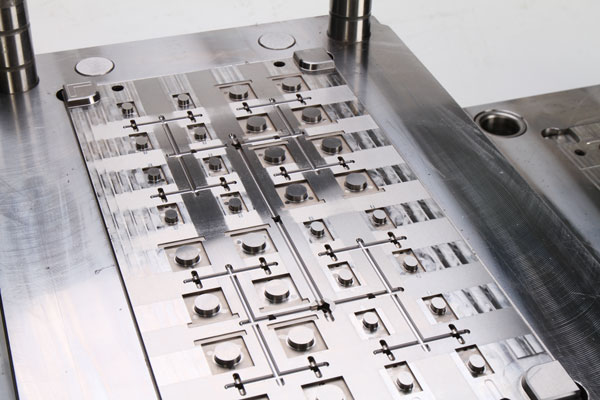

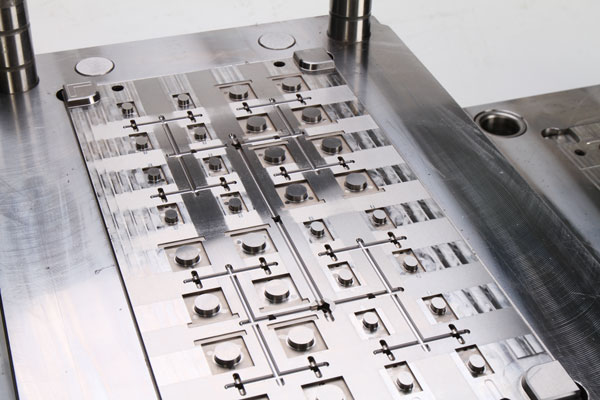

In the field of medical device manufacturing, multi-cavity mold technology has emerged as a cornerstone for enhancing production efficiency and reducing costs. From disposable syringes to precision respiratory masks, multi-cavity molds enable the simultaneous injection molding of multiple products, achieving exponential increases in capacity. However, this technology is not a panacea; its application requires a delicate balance between efficiency, precision, and cost. This article will analyze the advantages and disadvantages of medical multi-cavity molds, incorporating industry case studies and technical details.

1. Core Advantages of Medical Multi-Cavity Molds

1.1 Efficiency Multiplication and Cost Optimization

Multi-cavity molds integrate multiple cavities within a single mold, increasing the output per injection cycle by 5-8 times compared to traditional single-cavity molds. For example, a packaging company producing PE bottle caps upgraded to an "eight-cavity" mold, boosting daily output from 60,000 to 140,000 units and significantly reducing unit costs. In the medical field, this technology is particularly suited for the mass production of disposable consumables, such as infusion sets and blood collection tubes, effectively spreading fixed costs like mold depreciation and labor.

1.2 Consistency in Precision

Multi-cavity molds ensure dimensional consistency across products, with variations controlled within micrometers. For instance, a respiratory mask mold achieves integrated molding of components like valves and adjustable strap clips through slider and lifter mechanisms, with a mold lifespan exceeding 500,000 cycles and further reduced per-unit costs. Additionally, standardized designs minimize secondary processing needs, such as eliminating adhesive bonding steps, enhancing product uniformity.

1.3 Resource Conservation and Automation Compatibility

Multi-cavity molds reduce machine occupation and manual intervention, simplifying subsequent processes like gate trimming and cold runner recycling. A medical mold enterprise, for example, adopted a modular cavity group design with standardized interfaces for rapid replacement of partial cavities, adapting to multi-variety production. Meanwhile, IoT monitoring technology enables real-time tracking of cavity temperature, pressure, and predictive maintenance scheduling, advancing production automation.

2. Potential Challenges of Medical Multi-Cavity Molds

2.1 Design Complexity and Filling Balance Issues

The primary challenge of multi-cavity molds lies in ensuring uniform filling across all cavities. Improper runner design (e.g., asymmetric layouts or串联冷却水路, series-connected cooling channels) may lead to uneven filling, flash, or warpage. A packaging company's failed "eight-cavity" mold, for instance, suffered from a 12% defect rate due to insufficient pressure at the runner's end and inefficient cooling. After adopting an H-type balanced runner and independent cooling circuits, the defect rate dropped to 1.5%.

2.2 Mold Lifespan and Maintenance Costs

The complex structure of multi-cavity molds demands high-precision materials and processing. Medical molds often require high-hardness steels like S136 or NAK80, paired with insert designs for localized replacement of worn components. However, high-precision machining and heat treatment significantly increase costs, and mold lifespan is constrained by the stability of injection molding parameters. For example, fluctuations in injection speed, pressure, or melt temperature can accelerate cavity wear.

2.3 Customization Demands and Flexibility Limitations

Medical products' stringent requirements for materials, colors, and dimensions restrict the applicability of multi-cavity molds. A single mold cannot switch materials or colors during molding, and significant size differences among cavities may lead to insufficient filling. For instance, respiratory masks requiring size adjustments for children and adults necessitate modular designs, which increase mold complexity and costs.

3. Industry Trends: Breakthroughs Through Intelligence and Standardization

3.1 AI-Assisted Design and Simulation

AI technology will deeply integrate into multi-cavity mold design. By inputting a 3D product model, AI can automatically generate balanced runner solutions, optimize cooling channel layouts, and simulate melt flow behavior during injection. For example, a medical mold enterprise has achieved automatic adjustment of runner diameters from φ6mm to φ8mm, significantly improving filling uniformity.

3.2 Modularity and Standardization

Modular cavity group designs will become mainstream. Through standardized interfaces, enterprises can rapidly replace partial cavities to adapt to multi-variety production. For instance, a respiratory mask mold enterprise achieved a 30% efficiency boost by rapidly switching between pediatric and adult mask cavities through modular design.

3.3 Material and Process Innovation

The application of high-performance engineering plastics and biocompatible materials will further expand the boundaries of multi-cavity molds. For example, composite materials like medical silicone and polyurethane enhance mold wear and corrosion resistance, meeting the high-quality requirements of medical devices.

4. Conclusion: The Symbiosis of Efficiency and Precision

Medical multi-cavity mold technology is the foundation for scalable medical device production, but its application must overcome challenges like filling balance, mold lifespan, and customization demands. In the future, with the proliferation of AI design, modular manufacturing, and novel materials, multi-cavity molds will transition from "experience-driven" to "data-driven," finding an optimal balance between efficiency, precision, and cost. For medical enterprises, selecting multi-cavity molds requires a comprehensive assessment of product requirements, process capabilities, and long-term costs to gain a competitive edge.

Home

Home