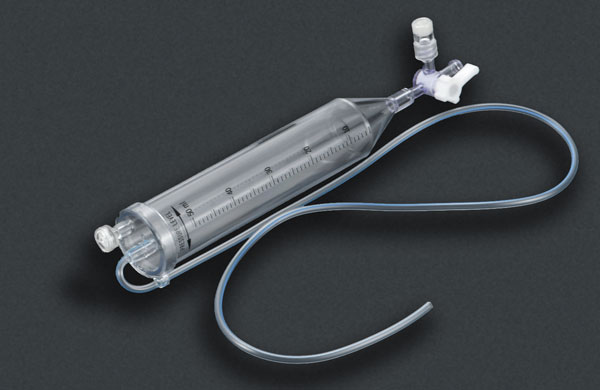

Medical devices serve as a crucial pillar of the modern healthcare system, where the precision and safety of their manufacturing directly impact patient lives. With advancements in materials science and precision manufacturing technologies, injection molding has emerged as a key technique in medical device production due to its efficiency, repeatability, and ability to produce complex components. From surgical instruments to implants, diagnostic equipment to rehabilitation aids, injection molding is widely applied in the manufacturing of various medical devices. So, how are high-quality medical devices produced through the injection molding process?

Typically, it involves the following main steps:

-

Design and Mold Development: Initially, product design and optimization are carried out based on the functional requirements of the medical device, ergonomic principles, and biocompatibility standards. Subsequently, Computer-Aided Design (CAD) software is utilized to design the mold, ensuring its precision and durability while considering ease of demolding and subsequent processing needs. Yize Mold, with its extensive experience and advanced technology, offers comprehensive services from design to mold manufacturing, ensuring high precision and long lifespan of the molds.

-

Material Selection: Medical-grade materials that comply with relevant standards are chosen based on the usage environment and requirements of the medical device, such as medical-grade plastics (PP, PE, PC, etc.), biodegradable materials, or special alloy materials. These materials must possess good biocompatibility, chemical stability, and necessary physical and mechanical properties.

-

Injection Molding: The selected material is heated to a molten state and injected into the pre-designed mold cavity under high pressure. After cooling and solidification, it forms the desired shape of the medical device component. This process requires strict control of parameters such as temperature, pressure, and injection speed to ensure consistency and stability of product quality.

-

Post-Processing and Assembly: The injection-molded components may undergo post-processing operations such as deburring, polishing, cleaning, and sterilization to meet the cleanliness and sterility requirements of medical devices. Subsequently, the components are precisely assembled according to the design requirements to form a complete medical device product.

-

Quality Inspection and Verification: Comprehensive quality inspections are conducted on the finished products, including but not limited to dimensional accuracy, physical properties, chemical properties, and biocompatibility tests, to ensure compliance with relevant domestic and international medical standards and regulatory requirements. Through a rigorous quality control system, the safety and effectiveness of every medical device are ensured.

Yize Mould – Your Trusted Partner for Medical Device Injection Molding Solutions

In the field of medical device injection molding, Yize Mould provides one-stop services from mold design, manufacturing to injection molding production with its outstanding technical strength, extensive industry experience, and strict quality management system. We deeply understand the extremely high requirements for precision, safety, and reliability of medical devices. Therefore, Yize Mold continuously introduces internationally advanced manufacturing technologies and equipment, optimizes production processes, and ensures that every product meets the highest standards. Choosing Yize Mold means choosing professionalism, efficiency, and peace of mind. Let's work together to create a bright future for medical device manufacturing.

Home

Home