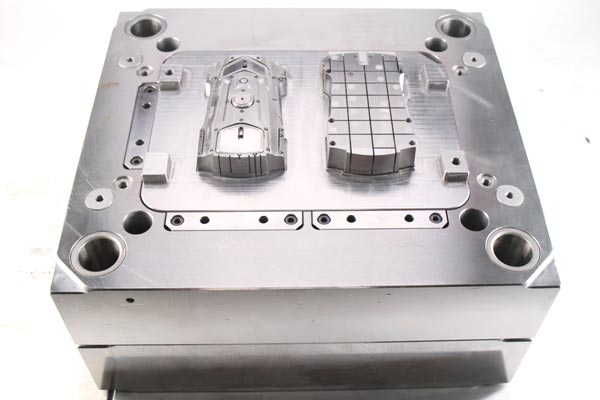

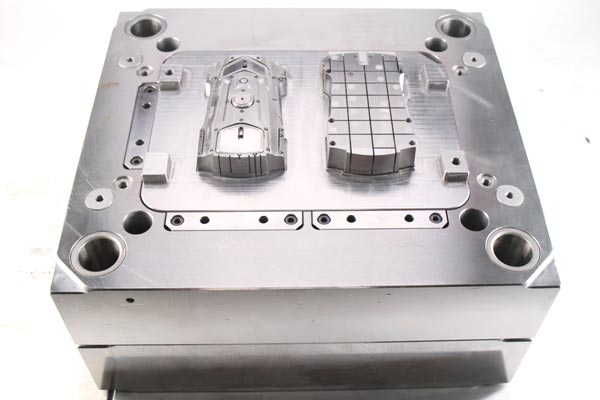

In the era of vigorous development of the manufacturing industry, injection molds, as key tools for plastic product molding, directly impact product quality and production efficiency. In recent years, with the continuous accumulation of experience in injection mold making and the steady improvement of manufacturing levels, the proportion of plastic products in various fields has been on the rise. For plastic products, scientific and reasonable injection mold design is the core factor in ensuring their quality. Among the overall mold design, the application of inserts is a particularly noteworthy issue, as they play important roles in multiple aspects.

Dealing with Complex Structures and Optimizing Processing and Venting

For parts with complex structures, deep ribs, or irregular shapes, adding inserts is generally adopted. This approach offers several advantages. In terms of processing, the use of inserts greatly facilitates the post-processing of injection molds. Since complex structures are often difficult to machine, insert design allows the complex parts to be divided into relatively simple individual components for processing, reducing the complexity of the machining process. Regarding venting, the presence of inserts can create additional venting channels, enabling the smooth discharge of gas within the mold. During the injection molding process, if the gas cannot be discharged in a timely manner, it will accumulate in the deep parts of the product, causing scorching and affecting product quality. The reasonable application of inserts can effectively prevent this problem and ensure the molding quality of the product.

Simplifying Deep Rib Processing and Enhancing Efficiency and Quality

When deep ribs need to be machined around the entire perimeter of the cavity, separation processing can be used for easier operation, and inserts play a key role in this process. By designing the deep rib parts as inserts, the inserts and other parts of the mold can be processed separately, significantly shortening the overall processing time. At the same time, the gaps formed after separation processing are conducive to venting, allowing the gas within the mold to be discharged more smoothly and reducing product defects caused by gas retention, thereby improving the quality of the molded products to better meet design requirements.

Enabling Product Diversification through Interchangeable Inserts

When a set of injection molds is required to produce products of multiple models and specifications, and these products only differ in some partial structures, interchangeable inserts are an extremely effective solution. By designing interchangeable inserts, when switching to the production of different models of products, only the corresponding inserts need to be replaced, without the need for large-scale modifications to the entire mold. This approach not only improves the versatility and flexibility of the mold, enabling it to quickly adapt to market demands for different products, but also greatly saves the time and cost of mold replacement, enhancing production efficiency.

Reinforcing Weak Parts and Facilitating Quick Replacement and Maintenance

In the fixed mold or moving mold of injection molds, there are some parts with weak compressive strength that are prone to damage. For these parts, it is advisable to prepare more inserts as spares. When these parts are damaged, the inserts can be quickly replaced without the need for complex repairs to the entire mold. This method can significantly save mold repair time, reduce production interruptions caused by mold repairs, ensure the continuity and stability of production, and improve the production efficiency of enterprises.

Focusing on Cost Control and Reducing Difficulty and Cycle Time

From the perspective of cost control, using insert design for protruding or circular parts of injection molds has significant advantages. On the one hand, inserts can be made using different materials and processes, allowing the selection of more cost-effective solutions according to actual needs, thereby saving mold manufacturing costs. On the other hand, inserts can divide complex structures into simple parts for separate processing, reducing the difficulty of machining. Different parts can be processed simultaneously, shortening the overall processing cycle time, further reducing production costs, and enhancing the market competitiveness of enterprises.

In conclusion, inserts have a wide and important application scope in injection mold design and structure. They can not only solve problems such as complex structure processing and venting but also enable the diversified production of products, reinforce weak parts of the mold, and contribute to cost control and shortened processing cycles. With the continuous development of injection mold technology, the application of inserts will become more mature and perfect, providing stronger support for the high-quality production of plastic products.

Home

Home